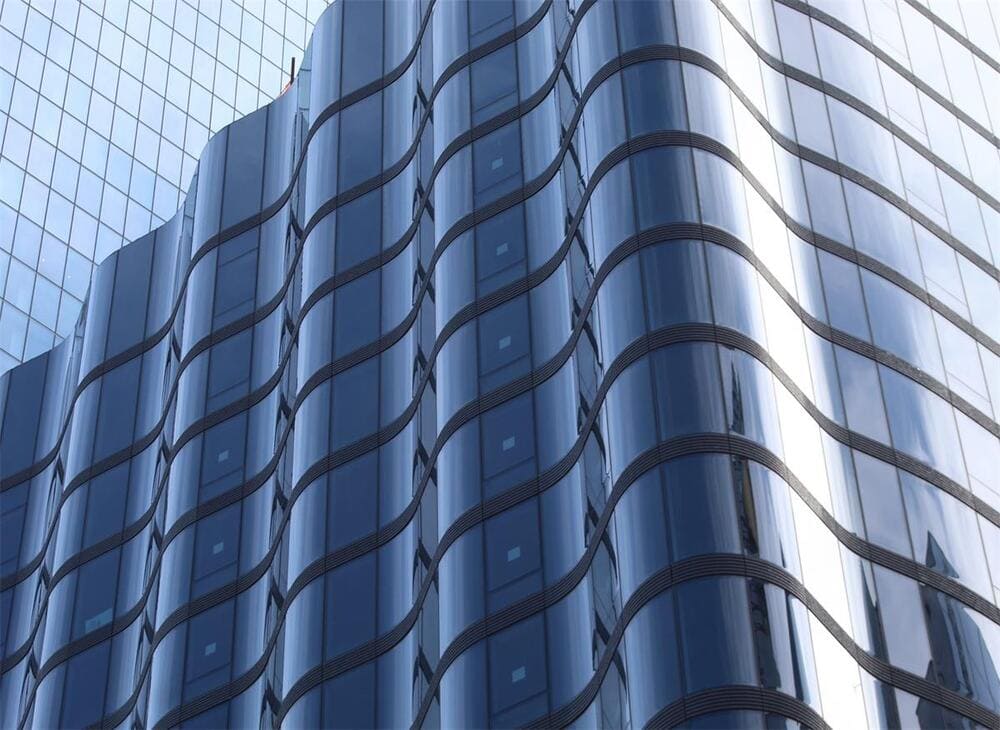

Curved Glass Walls

Curved glass walls are architectural glass panels bent to specific radii, ideal for modern façades, partitions, and displays. They combine aesthetic appeal with structural integrity, offering customizable options like tempered, laminated, and insulated glass for enhanced safety, soundproofing, and energy efficiency.

OrbGlass has been at the forefront of curved glass innovation in China. With a comprehensive product range including tempered, laminated, and compound curved glass, we cater to diverse needs in architecture and industry. Our cutting-edge facilities and dedication to quality make us the trusted choice for custom glass solutions globally.

What Are the Different Types of Curved Glass Walls

Curved glass walls come in various types, each offering unique benefits. The main types include tempered curved glass walls, known for their strength and safety; laminated curved glass walls, providing enhanced security and sound insulation; insulated curved glass walls, offering energy efficiency; and compound curved glass walls, featuring complex curves for distinctive designs.

Type of Curved Glass Walls

We’ve mastered all curved glass wall types since 2015. Whether you need fire-rated laminated panels for skyscrapers or ultra-thin tempered displays for electronics, our ISO-certified factory in Qingdao, China, delivers precision-engineered solutions tailored to your project’s exact specifications.

- Tempered Curved Glass Walls

Heat-treated for increased strength and safety, these walls are ideal for high-traffic areas and public spaces where durability and security are paramount. - Laminated Curved Glass Walls

Composed of multiple layers of glass bonded with plastic interlayers, these walls provide excellent sound insulation and enhanced security, with the glass holding together even if broken. - Compound Curved Glass Walls

Featuring bends in multiple directions, these walls allow for complex, three-dimensional shapes, perfect for unique architectural designs and prestigious projects. - Insulated Curved Glass Walls

Made with two or more glass panes separated by a spacer, these walls offer superior thermal insulation, making them ideal for energy-efficient and sustainable buildings.

Our Services for Curved Glass Walls

At OrbGlass, we provide end-to-end services for your curved glass wall projects. Our team offers custom design and engineering to create tailored solutions meeting your specifications. We handle precision manufacturing with advanced technology to produce high-quality curved glass, including tempered, laminated, and compound options. Additionally, we provide technical consultation to guide you on glass types and standards, plus efficient delivery from Qingdao, China, and after-sales support for maintenance needs.

-

Custom Solutions

-

Advanced Manufacturing

-

Expert Consultation

-

Timely Delivery

-

Reliable Support

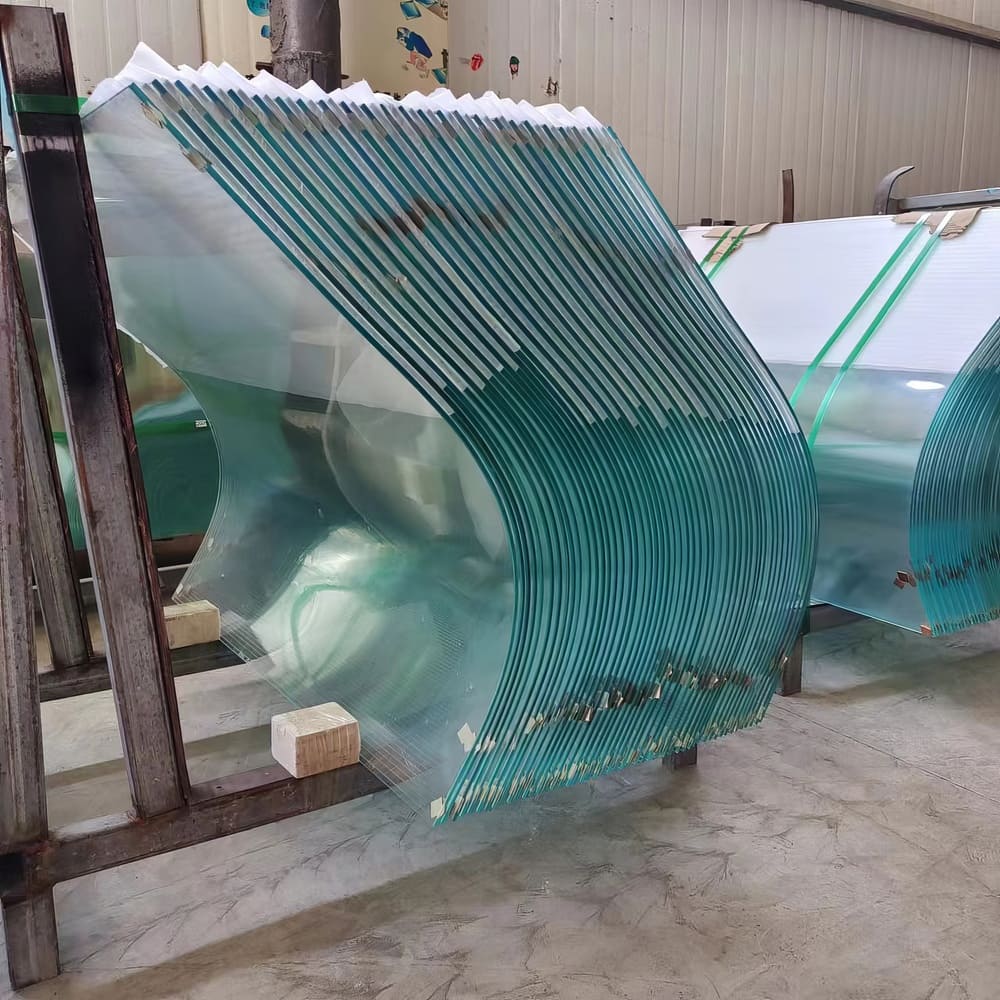

The Manufacturing Process of Curved Glass Walls

The manufacturing process of curved glass walls involves heating flat glass to a high temperature, shaping it into a curve using molds, and then cooling it rapidly to strengthen it. This tempering process by OrbGlass ensures durability and safety for architectural and industrial use.

- Design & Prototyping CAD modeling for precise curvature (radius ≥40″) and thickness (5-19mm).

- CNC Cutting Waterjet/grinder cutting to project dimensions (±0.5mm tolerance).

- Heat Bending Glass heated to 620°C in bending ovens, molded onto custom forms.

- Tempering/Laminating Rapid cooling for tempered strength or PVB interlayer bonding.

- Quality Inspection 3D scanning for curvature accuracy, stress tests, and certification checks (CE/SGCC).

Our Qingdao facility harnesses cutting-edge technology to produce Curved Glass Walls with unmatched precision. Our advanced equipment overcomes challenges like tight radii and large-scale designs, delivering customized, high-quality solutions for architectural, automotive, and restoration projects. Trust OrbGlass to bring your vision to life with expertise and innovation.

- 3 Advanced Flat and Curved Glass Tempering LinesProcess glass up to 3200mm x 5000mm, ensuring strength and safety for diverse applications.

- 2 Fully Automated Insulating Glass Production LinesProduce energy-efficient double/triple-glazed units, up to 3000mm x 4500mm, with ±0.2mm spacer accuracy.

- 1 High-Speed Double-Edge and 2 Four-Edge Grinding MachinesGrind edges at 6m/min with ±0.1mm precision, ensuring flawless finishes.

- 1 Precision Waterjet Cutting MachineCuts intricate shapes with ±0.5mm accuracy, supporting panels up to 4000mm x 6000mm.

- Advanced Flat and Curved Lamination EquipmentLaminates glass up to 3500mm x 5000mm with PVB interlayers for safety and UV protection.

Our advanced machinery ensures precision for ultra-small radius glass and oversized panels, meeting global standards (ISO 9001, CE). With continuous innovation and industry-standard contributions, OrbGlass delivers reliable, eco-friendly solutions.

Quality Control for Curved Glass Walls

we recognize that even the most advanced manufacturing equipment is only as reliable as the quality controls governing it. Curved glass demands millimeter-perfect precision, and defects like warping, micro-cracks, or inconsistent curvature can compromise structural integrity. Here’s how our 5-step quality assurance system eliminates risks at every stage:

-

Raw Material Inspection

Only use Grade A ultra-clear glass (iron content ≤0.015%) to prevent greenish tints. -

Pre-Production Calibration

3D-scanned bending molds must match CAD designs within ±0.1mm tolerance. -

In-Process Monitoring

Infrared thermal imaging detects heat distribution anomalies during tempering. -

Post-Production Testing

Laser scanners measure radius accuracy (±0.3mm) across 50+ data points.

Cost Structure of Curved Glass Walls

Curved glass walls are indeed more expensive than traditional walls due to their specialized manufacturing process and high-quality materials. Prices typically range from $100 to $500 per square foot, depending on factors like glass type, customization, and size. However, at OrbGlass, we offer competitive pricing that is significantly lower than what you might find in your local market, ensuring you get premium curved glass solutions at exceptional value.

- Material CostsThe price of the glass itself, varying by type (e.g., tempered, laminated) and specifications like thickness and size.

- Manufacturing CostsExpenses for the advanced bending and shaping process required for curved glass, utilizing our state-of-the-art production lines.

- Customization CostsAdditional charges for bespoke designs, special coatings, or unique features tailored to your project’s requirements.

- Shipping and LogisticsCosts for international transportation from our facility in Qingdao, China, leveraging our strategic location for efficient delivery.

- Installation CostsSeparate fees for professional installation, if required, as OrbGlass focuses on supplying high-quality glass.

- Certifications and ComplianceIncluded in our pricing to ensure your glass meets global standards like ISO 9001 and SGCC.

- Minimum Order QuantitiesPotential requirements for large-scale projects, affecting total cost in our B2B wholesale model.

Frequently Asked Questions

Is curved glass more expensive?

Curved glass is generally more expensive than flat glass due to the complex manufacturing process, which involves heating and shaping the glass using specialized molds. The cost can vary based on factors like glass type, size, and customization. At OrbGlass, we offer high-quality curved glass walls at competitive prices, ensuring exceptional value. Contact us for cost-effective solutions tailored to your project.

Are curved glass walls expensive?

Curved glass walls are typically more expensive than traditional walls, costing $100 to $500 per square foot due to specialized manufacturing and materials. Factors like glass type and customization affect pricing. At OrbGlass, we provide competitive pricing significantly lower than local markets, delivering premium curved glass walls at great value. Contact us for a custom quote.

Do they still make curved glass walls?

Yes, curved glass walls are still manufactured and widely used in modern architecture for their aesthetic and functional benefits. At OrbGlass, we specialize in producing high-quality curved glass walls, including tempered and laminated options, tailored to your needs. Contact us to discuss how we can enhance your project with our expertise.

What are the disadvantages of glass walls?

Glass walls can be expensive, fragile, and offer less privacy than traditional walls. They also require regular cleaning to maintain appearance. At OrbGlass, we mitigate these issues with durable, high-quality curved glass walls, offering privacy options like frosted glass and soundproofing features. Contact us to find solutions that balance functionality and aesthetics.

Is a glass wall cheaper than drywall?

No, glass walls, costing $100 to $500 per square foot, are more expensive than drywall, which ranges from $1 to $5 per square foot. At OrbGlass, we offer competitive pricing for our curved glass walls, ensuring value through durability and design. Contact us to explore cost-effective solutions for your space.

What is the alternative to glass walls?

Alternatives to glass walls include acrylic, polycarbonate, drywall, wood paneling, and brick. Acrylic and polycarbonate are lighter but less durable, while drywall and wood are cost-effective but lack transparency. At OrbGlass, our curved glass walls offer superior clarity and aesthetics. Contact us to see how our solutions elevate your project.

What is the cheapest option for interior walls?

Drywall, costing $1 to $5 per square foot, is the cheapest option for interior walls. For a modern, light-filled alternative, OrbGlass’s curved glass walls provide lasting value despite higher costs. Contact us to learn how our durable, energy-efficient glass walls can transform your space.

How much does it cost to do a glass wall per sq ft?

Installing a glass wall costs $30 to $140 per square foot, with curved glass walls potentially higher due to specialized manufacturing. At OrbGlass, we offer competitive pricing for high-quality curved glass walls, ensuring great value. Contact us for a detailed quote tailored to your project.

Curved Glass Walls Application Scenarios

Curved glass walls are widely used in modern architecture for facades and interior partitions, as well as in staircase railings and luxury furniture, providing both aesthetic beauty and functional benefits. At OrbGlass, we offer a range of curved glass solutions tailored to these applications, ensuring high quality and customization.

Architectural Façades & Skylights

Our curved tempered glass walls withstand extreme weather while creating iconic building exteriors. Used in Dubai’s Alama Tower (15m radius curves) and Berlin’s Climate Museum (CE-certified insulated units).

Industrial Safety Barriers

12-19mm curved laminated glass walls with PVB interlayers protect manufacturing facilities from impacts (EN 12600 Class 1 certified).

High-End Interior Partitions

Create seamless curved office dividers and hotel lobbies with 8-12mm laminated glass. Acid-etched or frosted options ensure privacy without compromising natural light flow

We Are Always Provide Best Curved Glass Walls For Your Project

Hear From Our Clients

We believe in creating long-term partnerships based on trust and quality. See what our clients say about working with us.

Curved Glass Walls Related Articles

What Is Curved Glass Called? (Complete Guide to Types)

2025-09-12

Top 9 Curved Glass Manufacturers Brazilian

2025-07-22

Top 9 Curved Glass Manufacturers in UAE 2025

2025-07-12

Top 8 Curved Glass Manufacturers South Africa 2025

2025-05-07

Top 7 Curved Glass Manufacturers Indian 2025

2025-05-07

Top 9 Curved Glass Manufacturers Australian 2025

2025-05-08

Top 10 Curved Glass Manufacturers UK 2025

2025-05-07

Top 10 Curved Glass Manufacturers USA 2025

2025-05-07

Top 10 Curved Glass Manufacturers 2025

2025-05-07

Get Started with OrbGlass Today!

Aerospace-grade CNC machines carve brass frames with micron-level accuracy, while AI vision systems inspect crystal cuts for refractive consistency. Even hidden parts undergo stress tests mimicking 10+ years of use.

- Material Traceability

Each brass sheet or crystal slab has a QR code linking to its origin and metallurgical report. - Self-Correcting Production

IoT-enabled machines adjust cutting paths in real time if material thickness varies. - Durability Validated

Salt spray chambers test finishes against humidity levels from Dubai villas to Nordic churches.