Curved Shower Glass

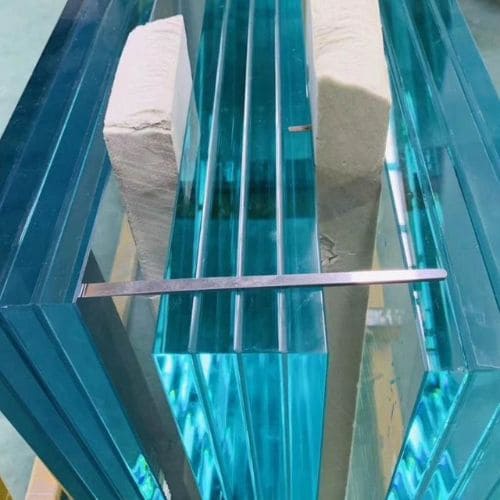

Curved shower glass, also known as bent shower glass, is a specially formed glass product used to create aesthetically pleasing and space-saving shower enclosures. It offers a unique design element, providing a smooth, continuous line unlike traditional angled panels.

With nearly 10 years of rich manufacturing experience, OrbGlass specializes in producing high-quality curved shower glass. We offer tempered, laminated, and composite curved glass solutions for various applications, including residential bathrooms, luxury hotels, and unique architectural projects.

What Are the Different Types of Curved Shower Glass

Curved shower glass comes in various types, primarily distinguished by glass treatment and shape. Common types include tempered curved glass for safety, laminated curved glass for enhanced security, and insulated curved units for thermal properties, available in diverse radii and configurations like quadrant, neo-angle, and custom curves.

Type of Curved Shower Glass

We’ve engineered every curved shower glass variant since 2015, serving architects and distributors globally. Based in Qingdao, China, our ISO/3C-certified factory specializes in customizing tempered, laminated, and composite curved glass for frameless enclosures, radius partitions, and high-end bathtub screens. Let us streamline your project with scalable, precision-crafted solutions.

- Frameless Curved Shower Doors Sleek, modern designs using 8–10mm tempered glass, ideal for open-concept bathrooms requiring minimalist aesthetics and easy maintenance.

- Semi-Frameless Sliding Enclosures Durable 6–8mm laminated glass panels with reinforced aluminum frames, suited for compact spaces needing smooth, space-saving operation.

- Arched Bathtub Screens Heat-bent 10–12mm glass with radii up to 2500mm, offering water containment and elegant transitions in freestanding tub setups.

- Radius Corner Shower Enclosures Custom-curved 6–8mm tempered glass for neo-angle installations, maximizing corner space with radii as small as 150mm.

- Laminated Safety Panels 10–12mm laminated glass with PVB interlayers, ensuring shatter resistance for family-friendly bathrooms or high-traffic hotels.

- Tinted/Frosted Curved Partitions Privacy-focused designs using ceramic-fritted or acid-etched surfaces, available in curved or flat-bent configurations.

Our Services for Curved Shower Glass

The Manufacturing Process of Curved Shower Glass

Curved shower glass typically carries a premium cost due to specialized manufacturing (e.g., slow bending processes for minimal distortion) and customization. However, OrbGlass offers competitive pricing by leveraging advanced production facilities in China and streamlined B2B workflows, ensuring high-quality curved glass at 20–40% below Western market rates.

While curved shower glass is often priced higher in Western markets (e.g., 400–1,500+ for prefabricated units), OrbGlass eliminates middlemen and optimizes bulk production, passing savings to clients. Our proximity to Qingdao’s logistics hubs further reduces shipping costs and lead times.

- Design and SpecificationCreate detailed blueprints based on client specifications for size, curvature, and glass type.

- Glass CuttingCut flat glass sheets to precise dimensions using a precision water jet cutting machine.

- Edge GrindingSmooth and polish edges with high-speed grinding machines for safety and aesthetics.

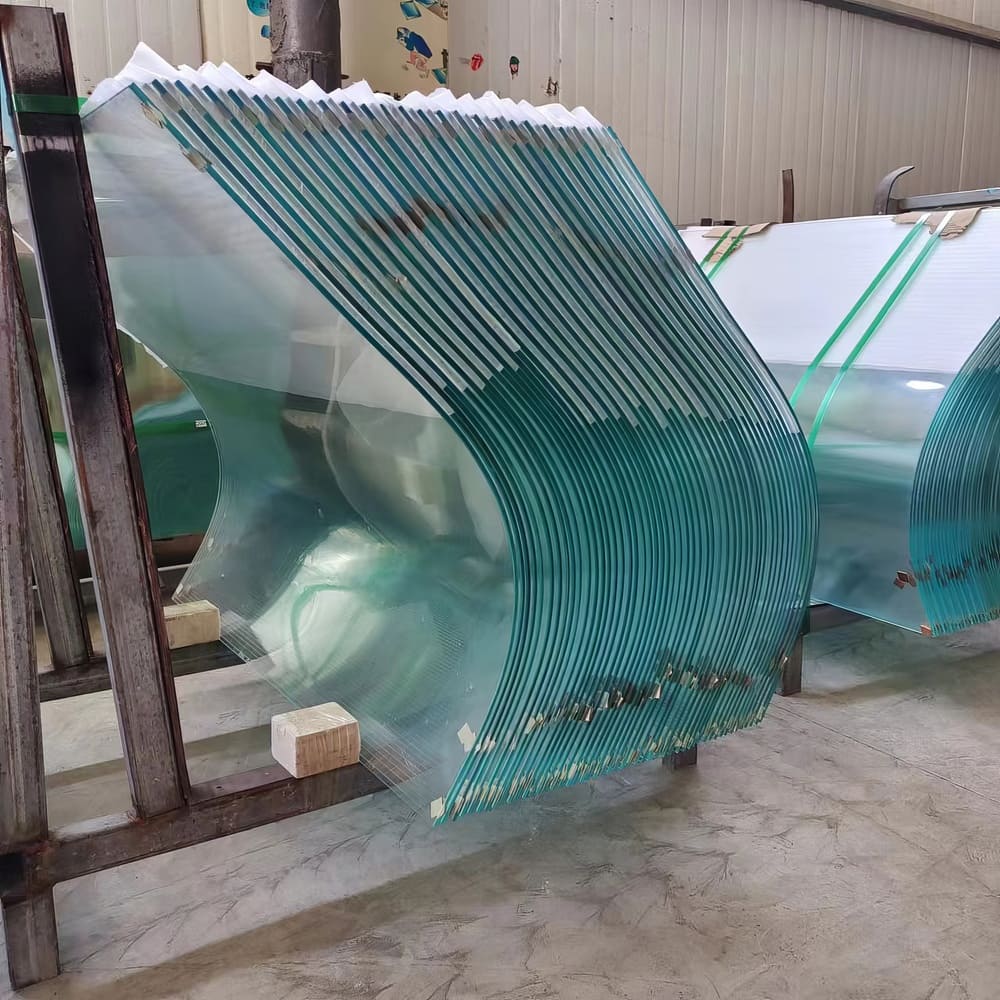

- BendingHeat glass in a furnace and shape it into curves using advanced bending molds.

- Tempering: Rapidly cool the curved glass to enhance strength and safety through tempering lines.

- Lamination (Optional)Bond multiple glass layers with interlayers for added durability, if required.

- Coating ApplicationApply energy-efficient or UV-protective coatings to meet specific project needs.

- Quality InspectionConduct rigorous checks to ensure compliance with ISO 9001 and international standards.

- PackagingSecurely package curved glass panels for safe transportation to clients.

Our Qingdao facility harnesses cutting-edge technology to produce Curved Shower Glass with unmatched precision. Our advanced equipment overcomes challenges like tight radii and large-scale designs, delivering customized, high-quality solutions for architectural, automotive, and restoration projects. Trust OrbGlass to bring your vision to life with expertise and innovation.

- 3 Advanced Flat and Curved Glass Tempering LinesProcess glass up to 3200mm x 5000mm, ensuring strength and safety for diverse applications.

- 2 Fully Automated Insulating Glass Production LinesProduce energy-efficient double/triple-glazed units, up to 3000mm x 4500mm, with ±0.2mm spacer accuracy.

- 1 High-Speed Double-Edge and 2 Four-Edge Grinding MachinesGrind edges at 6m/min with ±0.1mm precision, ensuring flawless finishes.

- 1 Precision Waterjet Cutting MachineCuts intricate shapes with ±0.5mm accuracy, supporting panels up to 4000mm x 6000mm.

- Advanced Flat and Curved Lamination EquipmentLaminates glass up to 3500mm x 5000mm with PVB interlayers for safety and UV protection.

Our advanced machinery ensures precision for ultra-small radius glass and oversized panels, meeting global standards (ISO 9001, CE). With continuous innovation and industry-standard contributions, OrbGlass delivers reliable, eco-friendly solutions.

Quality Control for Curved Shower Glass

we recognize that even the most advanced manufacturing equipment is only as reliable as the quality controls governing it. Curved glass demands millimeter-perfect precision, and defects like warping, micro-cracks, or inconsistent curvature can compromise structural integrity. Here’s how our 5-step quality assurance system eliminates risks at every stage:

-

Raw Material Inspection

Only use Grade A ultra-clear glass (iron content ≤0.015%) to prevent greenish tints. -

Pre-Production Calibration

3D-scanned bending molds must match CAD designs within ±0.1mm tolerance. -

In-Process Monitoring

Infrared thermal imaging detects heat distribution anomalies during tempering. -

Post-Production Testing

Laser scanners measure radius accuracy (±0.3mm) across 50+ data points.

Cost Structure of Curved Shower Glass

Curved shower glass typically costs 300–2,500+ depending on size, thickness, and customization. However, OrbGlass offers B2B wholesale pricing 30–50% below local markets due to advanced manufacturing efficiency and bulk-order advantages. As a factory-direct supplier in China, we eliminate middlemen markups. Our automated production, strategic sourcing of raw materials, and streamlined logistics enable competitive pricing without compromising ISO 9001 and AS1288-certified quality.

- Raw Material Grade Varies by glass type (e.g., tempered, laminated), thickness (6–19mm), and coatings (Low-E, UV protection).

- Customization Complexity Costs rise for non-standard curves, unique radii, or integrated designs (e.g., ImagInk ceramic printing).

- Production Technology Slow-bending processes (5–8 hours per panel) and precision cutting/edging increase labor and energy expenses.

- Certifications & Compliance Meeting AS1288, CE, or SGCC standards adds testing/QA costs.

- Logistics & Packaging Oversize shipping fees, crating for fragile glass, and import tariffs.

- After-Sales Support Includes warranties (e.g., 25-year fade resistance) and technical assistance.

Frequently Asked Questions

What are the benefits of curved shower glass?

Curved shower glass enhances bathroom aesthetics with sleek, modern designs while maximizing space efficiency. Its ergonomic shape improves water containment and reduces leaks. OrbGlass offers tempered or laminated curved glass options, combining safety, durability, and customization to meet architectural or residential needs.

Is curved shower glass more expensive than flat panels?

Yes, curved shower glass typically costs 20-40% more due to specialized manufacturing processes. However, OrbGlass provides cost-effective solutions through bulk B2B pricing and advanced production techniques, ensuring high-quality curved glass at competitive rates for global clients.

Can curved shower glass be customized for unique designs?

Absolutely. OrbGlass specializes in bespoke curved glass solutions, tailoring radius, thickness (4-12mm), and coatings (anti-fog, low-E) to project specifications. Our CNC bending technology supports complex shapes, ideal for luxury bathrooms or commercial spaces.

How durable is curved tempered shower glass?

Curved tempered glass is 4-5x stronger than standard glass, with heat-treated surfaces resisting cracks and impacts. OrbGlass products meet ASTM/EN safety standards, ensuring shatter-resistance for worry-free installations in high-traffic environments.

What maintenance does curved shower glass require?

Daily cleaning with pH-neutral solutions preserves clarity. OrbGlass offers optional hydrophobic coatings to repel water stains and mineral buildup, reducing maintenance by 70% while extending product lifespan.

Are curved shower enclosures leak-proof?

Properly installed curved enclosures minimize leaks via precision-engineered seals. OrbGlass includes pre-installed silicone gaskets and provides installation guides to ensure watertight performance, backed by a 10-year warranty on sealing systems.

Can curved glass panels fit small bathrooms?

Yes. OrbGlass designs compact curved enclosures (minimum radius 300mm) to optimize space in bathrooms as small as 1.5m². Our engineers provide 3D modeling to visualize layouts before production.

Does curved glass work for bathtub screens?

Yes. OrbGlass produces curved bathtub screens in 4-8mm tempered glass, customizable with chrome/black finishes. Our designs meet ISO 9001 standards for safety and ergonomic comfort.

How long does curved glass production take?

Standard orders ship in 15-20 days. OrbGlass accelerates lead times to 10 days for urgent projects via our 25,000㎡ facility with 3 automated bending lines, serving 20+ countries efficiently.

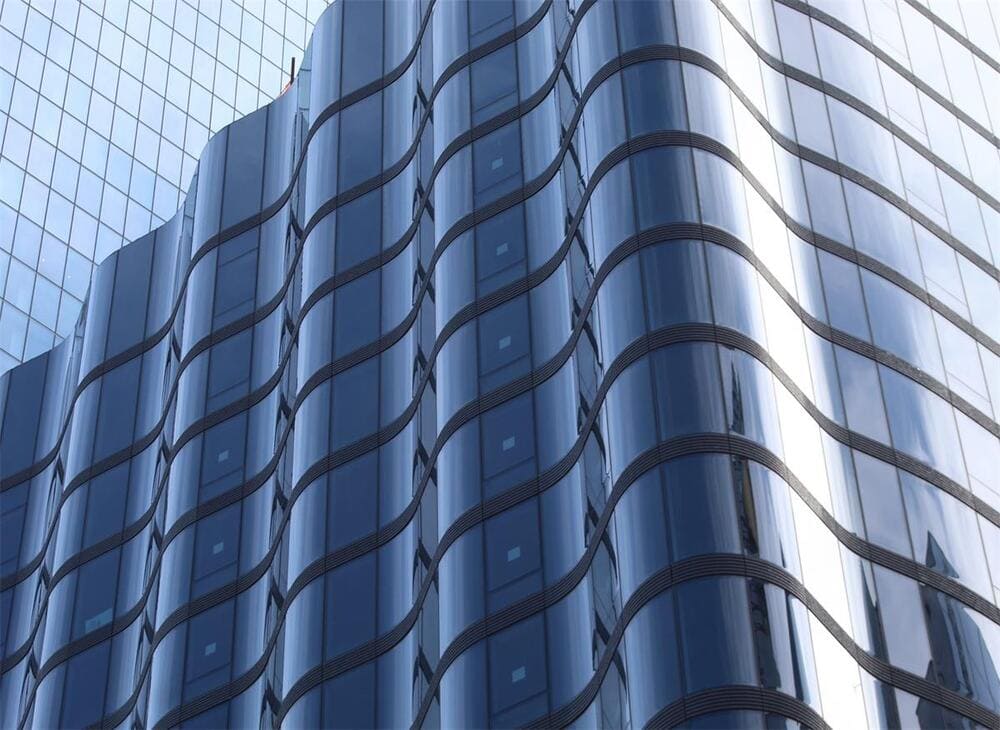

Curved Shower Glass Application Scenarios

Curved shower glass enhances modern spaces with sleek aesthetics and functionality. Key applications include luxury bathrooms, hotels, spas, commercial buildings, and accessibility-focused designs. OrbGlass delivers custom-curved solutions (6–19mm thickness, tempered/laminated options) meeting ISO 9001 and CE standards, ideal for seamless integration and durability.

Luxury Residential Bathrooms

Curved shower glass elevates master bathrooms with frameless enclosures or freestanding tub screens. OrbGlass offers custom radii (up to 180° arcs) and frosted/etched finishes for privacy, paired with anti-slip coatings for safety. Ideal for open-concept layouts seeking visual flow.

Accessible Bathing Spaces

Curved shower screens improve accessibility with barrier-free entry and reinforced grab-bar mounts. OrbGlass uses 10–12mm tempered glass with low-iron clarity for visibility, meeting ADA compliance standards for senior care or healthcare facilities.

Hotel & Spa Facilities

Premium curved shower enclosures create spa-like luxury in hospitality settings. OrbGlass provides tempered glass (8–12mm) with sound-dampening properties, ideal for high-traffic areas. Customizable LED-integrated designs enhance ambiance while meeting commercial safety codes.

We Are Always Provide Best Curved Shower Glass For Your Project

Hear From Our Clients

We believe in creating long-term partnerships based on trust and quality. See what our clients say about working with us.

Curved Shower Glass Related Articles

What Is Curved Glass Called? (Complete Guide to Types)

2025-09-12

Top 9 Curved Glass Manufacturers Brazilian

2025-07-22

Top 9 Curved Glass Manufacturers in UAE 2025

2025-07-12

Top 8 Curved Glass Manufacturers South Africa 2025

2025-05-07

Top 7 Curved Glass Manufacturers Indian 2025

2025-05-07

Top 9 Curved Glass Manufacturers Australian 2025

2025-05-08

Top 10 Curved Glass Manufacturers UK 2025

2025-05-07

Top 10 Curved Glass Manufacturers USA 2025

2025-05-07

Top 10 Curved Glass Manufacturers 2025

2025-05-07

Get Started with OrbGlass Today!

Aerospace-grade CNC machines carve brass frames with micron-level accuracy, while AI vision systems inspect crystal cuts for refractive consistency. Even hidden parts undergo stress tests mimicking 10+ years of use.

- Material Traceability

Each brass sheet or crystal slab has a QR code linking to its origin and metallurgical report. - Self-Correcting Production

IoT-enabled machines adjust cutting paths in real time if material thickness varies. - Durability Validated

Salt spray chambers test finishes against humidity levels from Dubai villas to Nordic churches.