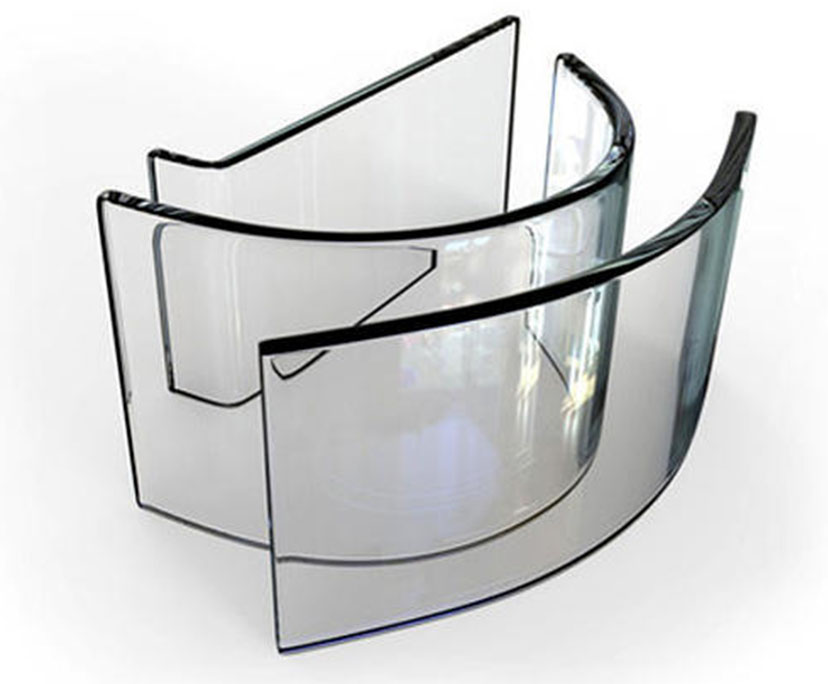

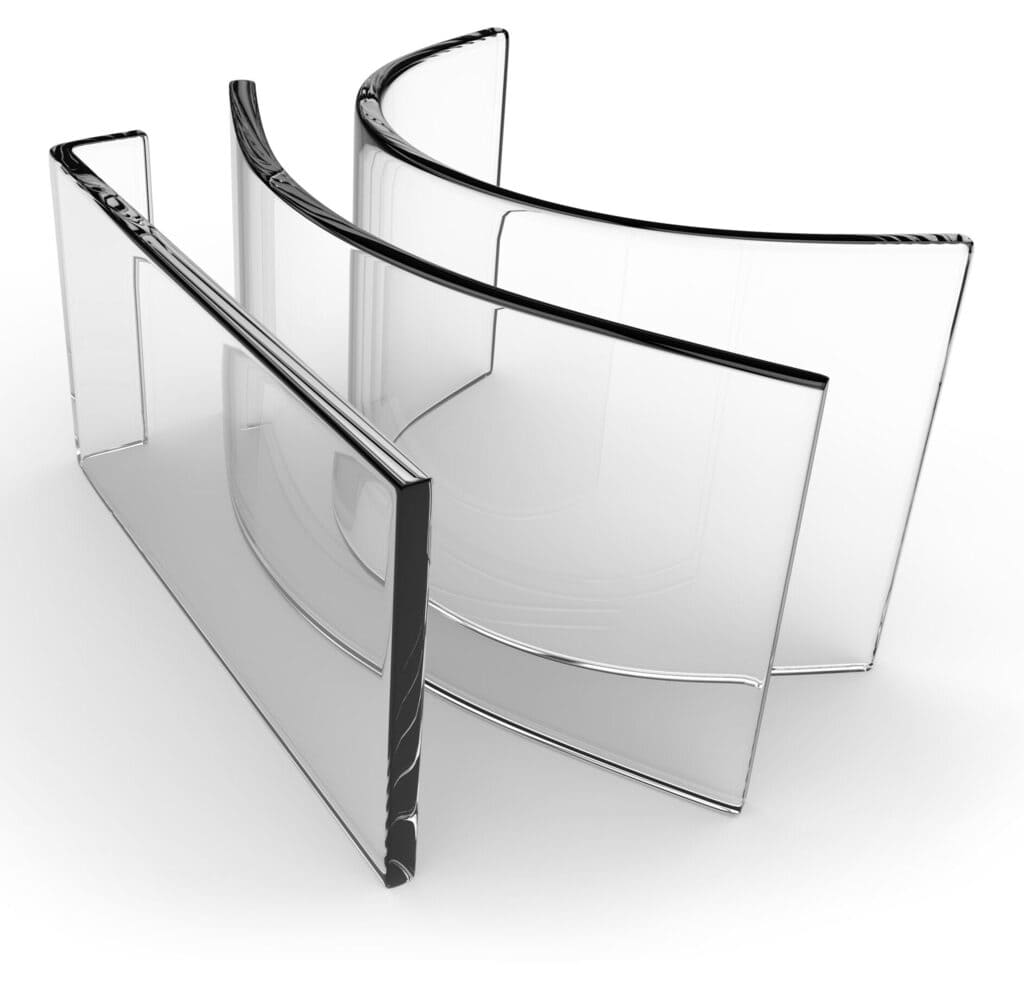

Curved Laminated Glass

What is Curved Laminated Glass?

Curved Laminated Glass is a safety glass made by bonding multiple glass layers with an interlayer, typically PVB, and shaping them into a curve. It offers enhanced safety, sound insulation, and UV protection, perfect for curved architectural facades and automotive windshields.

OrbGlass, based in Qingdao, China, brings nearly a decade of expertise in crafting Curved Laminated Glass. We produce customized tempered, laminated, and composite curved glass, serving B2B clients globally with tailored solutions for architectural and industrial needs.

What Are the Different Types of Curved Laminated Glass

Curved Laminated Glass includes types like Curved Tempered Laminated Glass for strength, Curved Annealed Laminated Glass for cost-efficiency, and Curved Heat-Strengthened Laminated Glass for balance. Specialized options like Bullet-Resistant and Bird-Safe Curved Glass enhance safety and sustainability, optimizing for laminated curved glass and safety glass laminated searches.

Type of Curved Laminated Glass

With nearly a decade of experience and advanced facilities, we offer tailored solutions for architectural and industrial needs, ensuring precision and quality in every custom order.

- Curved Tempered Laminated Glass

Combines tempered glass strength with lamination safety, perfect for high-impact uses like windshields and facades. - Curved Annealed Laminated Glass

A budget-friendly option using annealed glass, suited for decorative interiors with lower stress demands. - Curved Heat-Strengthened Laminated Glass

Offers moderate strength and affordability, ideal for curved railings and partitions. - Bullet-Resistant Curved Glass

Designed for security, providing ballistic protection while retaining curved aesthetics. - Bird-Safe Curved Glass

Incorporates patterns to prevent bird collisions, supporting eco-friendly architectural designs. - Curved Insulated Laminated Glass

Features insulation for energy efficiency, great for sustainable curved windows and facades.

Our Services for Curved Laminated Glass

We offer comprehensive services for Curved Laminated Glass to meet your project needs. Our services include custom design and engineering tailored to your specifications, precision manufacturing with advanced technology for accurate curvature and size, and rigorous quality testing to ensure safety and durability. We provide global logistics from Qingdao, China, and expert technical support from design to installation, delivering reliable solutions for architectural and industrial applications.

- Precision

- Strength

- Aesthetics

- Versatility

- Eco-Friendly

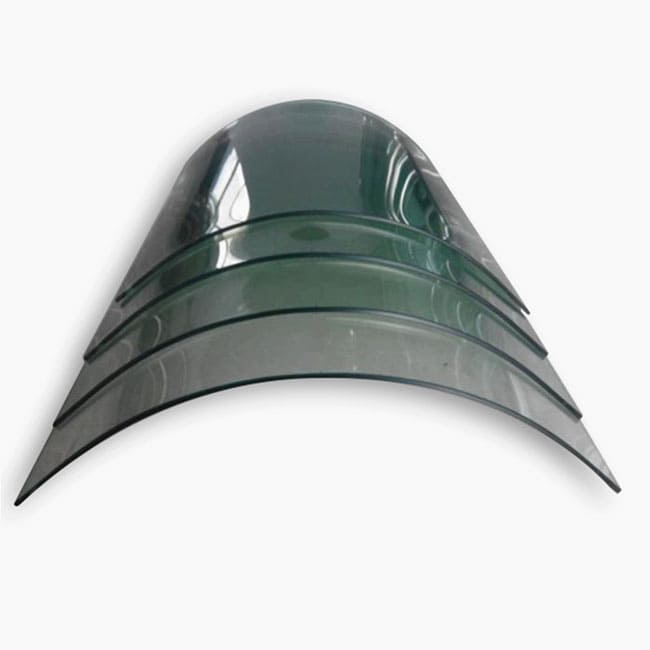

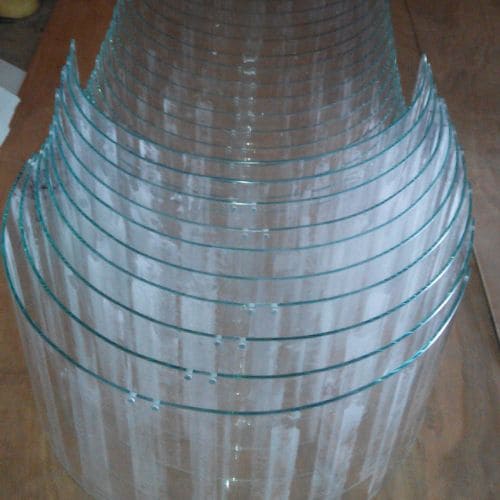

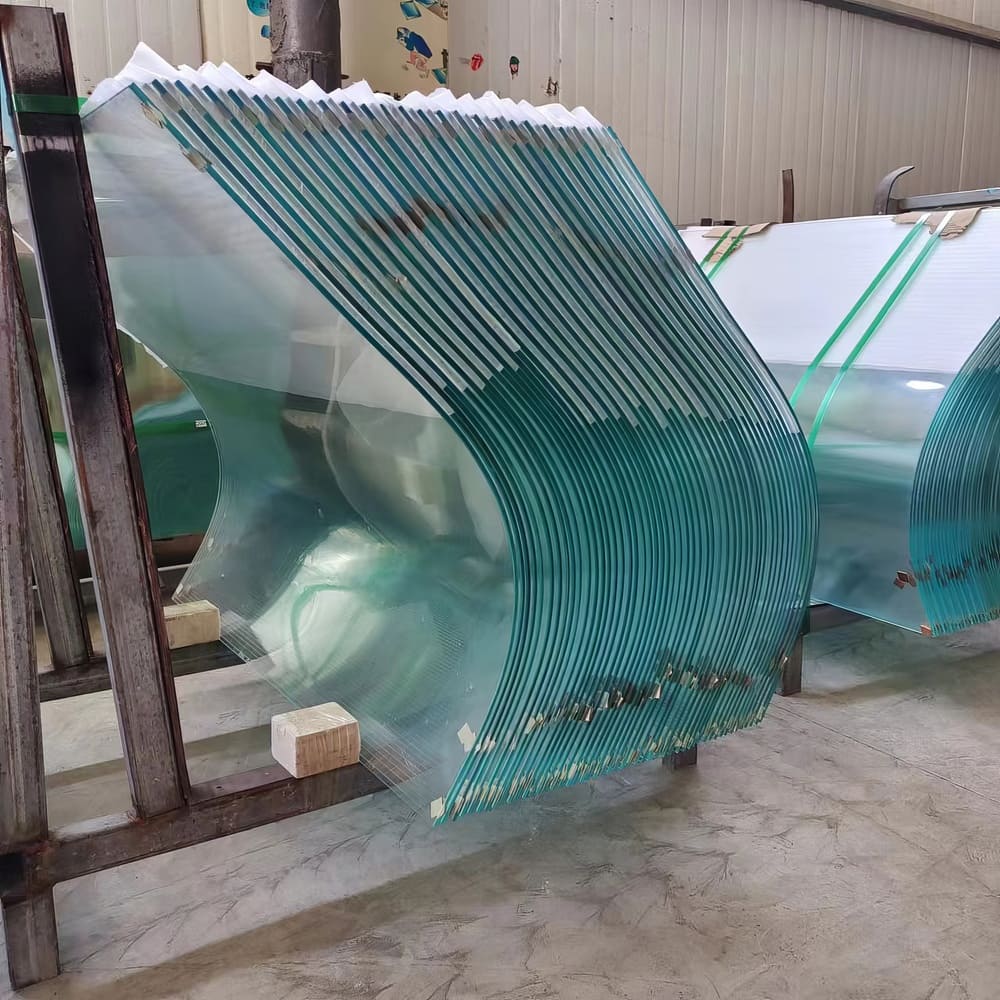

The Manufacturing Process of Curved Laminated Glass

Curved Laminated Glass, produced by OrbGlass in Qingdao, China, is made by heating flat glass to 600°C, shaping it over a mold, and laminating it with a PVB interlayer under heat and pressure. This ensures safety, strength, and aesthetic appeal for architectural and industrial use.

- Glass Selection High-quality flat glass sheets are chosen for curving and lamination suitability.

- Cutting Glass is precisely cut to size and shape before the curving process begins.

- Heating Glass is heated in a furnace to approximately 600°C until pliable.

- Curving Softened glass is molded into the desired curvature using a custom mold.

- Cooling Curved glass is slowly cooled to set its shape and reduce stress.

- Cleaning Surfaces are cleaned to remove impurities before lamination.

- Interlayer Placement A PVB interlayer is placed between two curved glass sheets.

- Lamination Layers are bonded in an autoclave using heat and pressure for durability.

- Inspection Final product is inspected to meet safety, quality, and design standards.

Our Qingdao facility harnesses cutting-edge technology to produce Curved Laminated Glass with unmatched precision. Our advanced equipment overcomes challenges like tight radii and large-scale designs, delivering customized, high-quality solutions for architectural, automotive, and restoration projects. Trust OrbGlass to bring your vision to life with expertise and innovation.

- 3 Advanced Flat and Curved Glass Tempering LinesProcess glass up to 3200mm x 5000mm, ensuring strength and safety for diverse applications.

- 2 Fully Automated Insulating Glass Production LinesProduce energy-efficient double/triple-glazed units, up to 3000mm x 4500mm, with ±0.2mm spacer accuracy.

- 1 High-Speed Double-Edge and 2 Four-Edge Grinding MachinesGrind edges at 6m/min with ±0.1mm precision, ensuring flawless finishes.

- 1 Precision Waterjet Cutting MachineCuts intricate shapes with ±0.5mm accuracy, supporting panels up to 4000mm x 6000mm.

- Advanced Flat and Curved Lamination EquipmentLaminates glass up to 3500mm x 5000mm with PVB interlayers for safety and UV protection.

Our advanced machinery ensures precision for ultra-small radius glass and oversized panels, meeting global standards (ISO 9001, CE). With continuous innovation and industry-standard contributions, OrbGlass delivers reliable, eco-friendly solutions.

Quality Control for Curved Laminated Glass

we recognize that even the most advanced manufacturing equipment is only as reliable as the quality controls governing it. Curved glass demands millimeter-perfect precision, and defects like warping, micro-cracks, or inconsistent curvature can compromise structural integrity. Here’s how our 5-step quality assurance system eliminates risks at every stage:

-

Raw Material Inspection

Only use Grade A ultra-clear glass (iron content ≤0.015%) to prevent greenish tints. -

Pre-Production Calibration

3D-scanned bending molds must match CAD designs within ±0.1mm tolerance. -

In-Process Monitoring

Infrared thermal imaging detects heat distribution anomalies during tempering. -

Post-Production Testing

Laser scanners measure radius accuracy (±0.3mm) across 50+ data points.

Cost Structure of Curved Laminated Glass

Purchasing Curved Laminated Glass can seem expensive due to its specialized manufacturing and customization. However, OrbGlass offers competitive pricing, leveraging advanced facilities and efficient production in Qingdao, China, to deliver high-quality, cost-effective solutions for architectural and industrial needs. While Curved Laminated Glass is often pricier in local markets, OrbGlass provides significantly lower prices. Our direct manufacturing and strategic location ensure cost savings without sacrificing quality, making us a trusted global partner for B2B clients.

- Customization Costs Expenses for tailored design and engineering to meet project specs.

- Material Costs High-quality glass and interlayers for lamination.

- Manufacturing Costs Advanced machinery and skilled labor for production.

- Quality Assurance Costs Rigorous testing to ensure safety and quality.

- Packaging Costs Secure packaging to prevent transit damage.

- Shipping and Logistics Costs Transport from Qingdao to the client’s location.

- Installation Costs Professional installation, if needed.

- After-Sales Support Costs Technical support and post-installation assistance.

Frequently Asked Questions

Can laminated glass be curved?

Yes, laminated glass can be curved by heating and molding it before laminating with an interlayer. This ensures safety and unique designs. OrbGlass, based in Qingdao, China, crafts high-quality Curved Laminated Glass for your architectural needs.

Is curved glass expensive?

Curved glass costs more than flat glass due to its complex production process. Prices depend on size, curvature, and customization. OrbGlass offers competitive pricing and premium Curved Laminated Glass tailored to your budget.

What is curved glass called?

Curved glass is known as bent glass or curved laminated glass, based on its type. It’s ideal for modern designs. OrbGlass supplies various curved glass options for architecture and industry.

How is Curved Laminated Glass made?

It’s produced by heating flat glass, shaping it, and laminating it with an interlayer for strength and safety. OrbGlass uses cutting-edge technology in Qingdao to deliver precise Curved Laminated Glass.

What are the benefits of Curved Laminated Glass?

It offers safety, sound insulation, UV protection, and stunning aesthetics. Ideal for innovative designs, OrbGlass provides Curved Laminated Glass to enhance your project’s functionality and appeal.

Can burglars break laminated glass?

Laminated glass resists breaking as its interlayer holds shards together, boosting security. OrbGlass manufactures durable Curved Laminated Glass for enhanced protection in any application.

What is the lifespan of laminated glass?

With proper care, laminated glass lasts decades, depending on environment and maintenance. OrbGlass ensures long-lasting Curved Laminated Glass with superior craftsmanship.

Can Curved Laminated Glass be customized?

Yes, it’s customizable in size, shape, curvature, and features like coatings. OrbGlass, a leader in Qingdao, delivers bespoke Curved Laminated Glass for your unique needs.

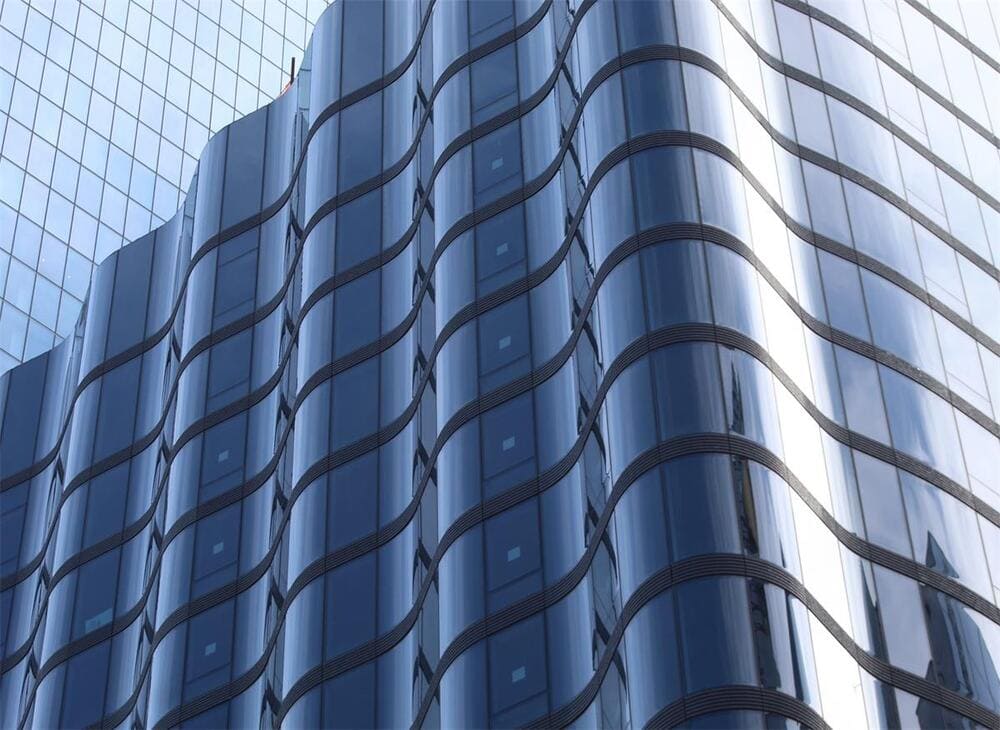

Curved Laminated Glass Application Scenarios

Curved Laminated Glass is used in architectural facades, automotive windshields, interior design, display cases, aquariums, elevator cabs, and staircases. Its safety, sound insulation, UV protection, and aesthetic versatility make it ideal for modern, innovative designs across industries.

Architectural Facades

Curved Laminated Glass enhances building exteriors with sleek, flowing lines. Ideal for skyscrapers and museums, it combines safety and energy efficiency. OrbGlass offers customized solutions from Qingdao, China, for stunning architectural projects.

Staircases and Balustrades

In staircases and balustrades, Curved Laminated Glass ensures safety and sophistication. Durable for high-traffic areas, it adds elegance. OrbGlass offers customized solutions for architectural needs.

Interior Design

In interiors, Curved Laminated Glass creates stylish partitions, doors, and furniture. Its customizable shapes elevate aesthetics. OrbGlass delivers tailored, precision-crafted glass for unique interior design projects.

We Are Always Provide Best Curved Laminated Glass For Your Project

Hear From Our Clients

We believe in creating long-term partnerships based on trust and quality. See what our clients say about working with us.

Curved Laminated Glass Related Articles

What Is Curved Glass Called? (Complete Guide to Types)

2025-09-12

Top 9 Curved Glass Manufacturers Brazilian

2025-07-22

Top 9 Curved Glass Manufacturers in UAE 2025

2025-07-12

Top 8 Curved Glass Manufacturers South Africa 2025

2025-05-07

Top 7 Curved Glass Manufacturers Indian 2025

2025-05-07

Top 9 Curved Glass Manufacturers Australian 2025

2025-05-08

Top 10 Curved Glass Manufacturers UK 2025

2025-05-07

Top 10 Curved Glass Manufacturers USA 2025

2025-05-07

Top 10 Curved Glass Manufacturers 2025

2025-05-07

Get Started with OrbGlass Today!

Aerospace-grade CNC machines carve brass frames with micron-level accuracy, while AI vision systems inspect crystal cuts for refractive consistency. Even hidden parts undergo stress tests mimicking 10+ years of use.

- Material Traceability

Each brass sheet or crystal slab has a QR code linking to its origin and metallurgical report. - Self-Correcting Production

IoT-enabled machines adjust cutting paths in real time if material thickness varies. - Durability Validated

Salt spray chambers test finishes against humidity levels from Dubai villas to Nordic churches.