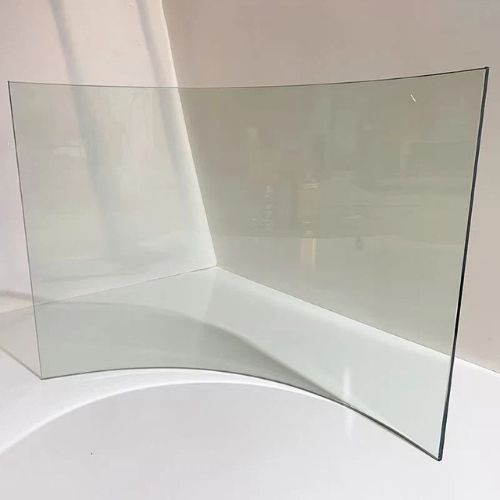

Curved Greenhouse Glass Panels

Curved greenhouse glass panels are bent glass sheets used in greenhouses for their aesthetic appeal, improved light diffusion, and structural benefits. Made from tempered or laminated glass, they offer strength, safety, and energy efficiency, making them ideal for modern, sustainable greenhouse designs.

With over 9 years of expertise, OrbGlass specializes in customized curved greenhouse glass panels, including tempered, laminated, and composite options. Certified with ISO 9001, we ensure high-quality, safe products for various greenhouse designs. Our tailored solutions and exceptional service make procurement seamless.

What Are the Different Types of Curved Greenhouse Glass Panels

Curved greenhouse glass panels include tempered, laminated, insulated, low-E coated, and composite variants. Common designs feature arched, single/double-curved, or multi-panel configurations, optimized for durability, light diffusion, UV protection, and thermal efficiency in diverse climates.

Type of Curved Greenhouse Glass Panels

We’ve engineered all curved greenhouse glass types for global clients, from Germany’s precision-driven designs to America’s large-scale installations. Our expertise ensures tailored solutions for structural integrity, aesthetic appeal, and sustainability, backed by certifications like ISO 9001 and CE.

- Tempered Curved Glass Heat-treated for 5x strength, ideal for impact-resistant greenhouse roofs and walls. Shatters safely into granular pieces.

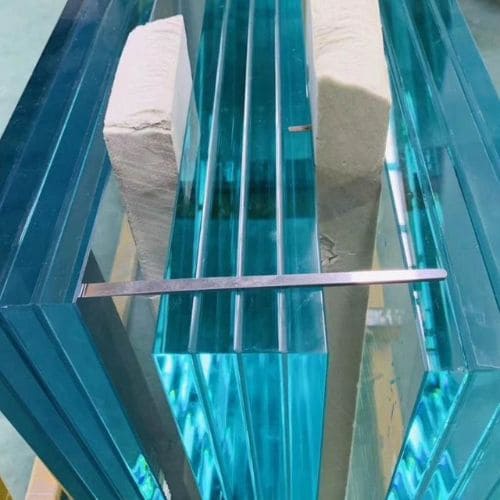

- Laminated Curved Glass PVB-interlayered panels offering superior safety, noise reduction, and 99% UV blocking for delicate plants.

- Insulated Curved Units Double-glazed with argon gas for thermal efficiency, reducing energy costs in extreme climates.

- Low-E Coated Curved Glass Energy-saving infrared reflection, maintaining consistent temperatures while maximizing light transmission.

- Arched Multi-Panel Systems Modular designs for seamless large-span greenhouses, using precision-bent glass for uniform curvature.

Our Services for Curved Greenhouse Glass Panels

OrbGlass delivers precision-crafted curved greenhouse glass panels tailored to your specifications. We offer custom design support, large-scale production of tempered/laminated/composite glass in any curvature, size, and thickness, and global logistics from Qingdao. Our services include technical consultation, certified manufacturing (ISO/CE/3C), and bulk order fulfillment—ensuring seamless integration into architectural or industrial projects.

- Precision engineering

- Advanced glass technology

- Global certification compliance

- Rapid bulk production

- OEM expertise

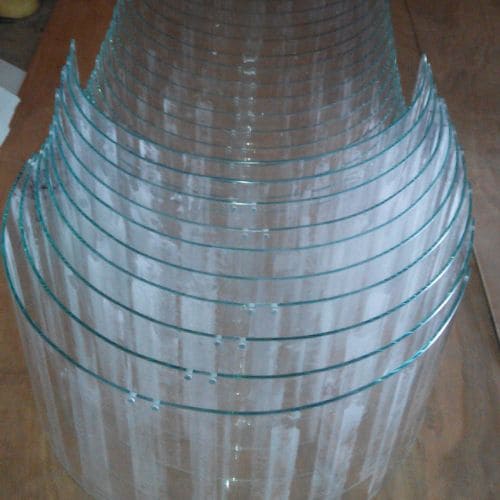

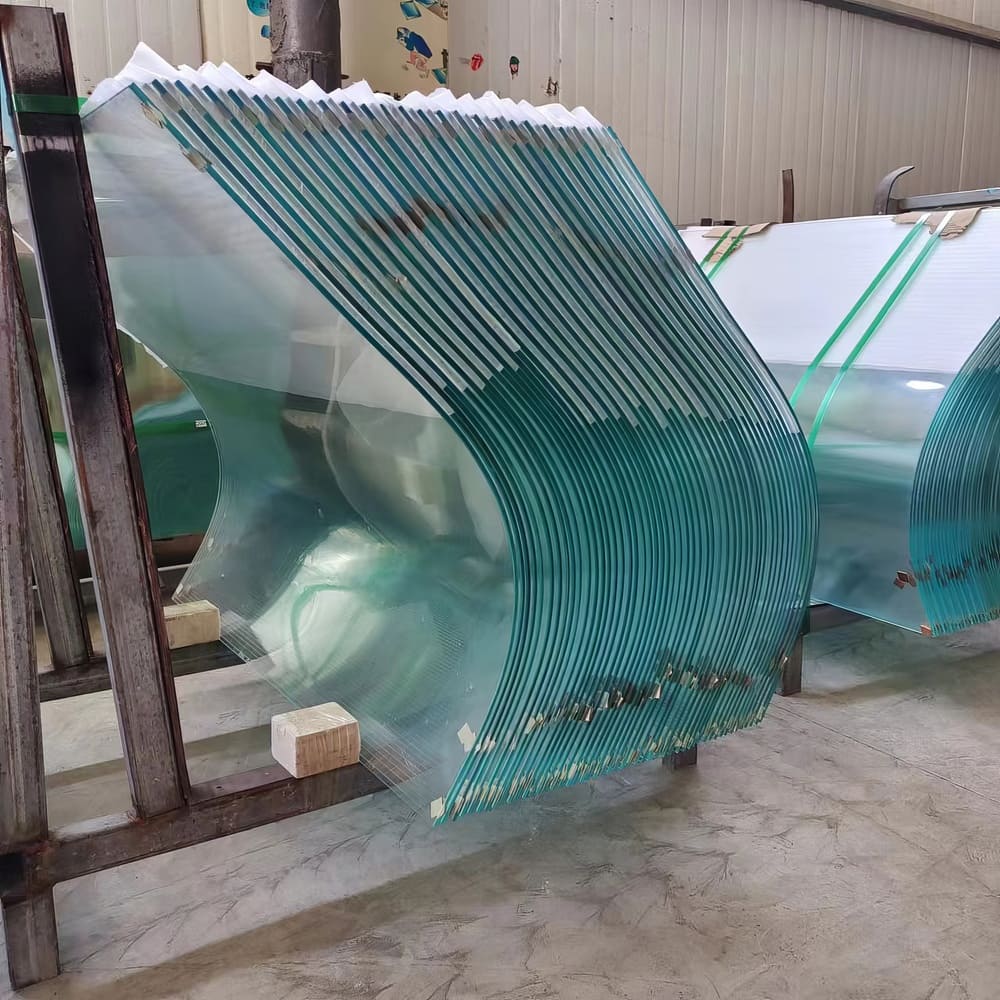

The Manufacturing Process of Curved Greenhouse Glass Panels

Curved Greenhouse Glass Panels are manufactured by designing and cutting high-quality glass, heating it to 600-700°C, shaping it over a mold, and cooling it. Depending on the type, the glass may be tempered for strength, laminated for safety, and coated for energy efficiency and UV protection.

- Design Customize panel specifications based on customer requirements for curvature, size, and glass type.

- Select Glass Choose high-quality float glass suitable for curving and greenhouse applications.

- Cut Glass Precisely cut the glass to the required dimensions using advanced cutting equipment.

- Clean Glass Thoroughly clean the glass to remove any impurities that could affect the curving process.

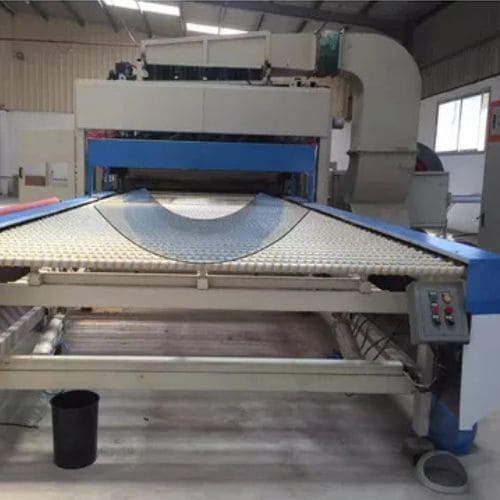

- Heat and Curve Heat the glass to approximately 600-700°C and shape it over a custom mold to achieve the desired curvature.

- Cool or Temper Slowly cool the glass for standard curved panels or rapidly cool it for tempered curved glass to enhance strength.

- Laminate (Optional) For laminated curved glass, bond two or more curved glass panels with an interlayer for added safety and insulation.

- Apply Coatings Apply energy-efficient coatings, such as Low-E coatings, to improve thermal insulation and provide UV protection.

- Quality Control Conduct rigorous inspections to ensure the panels meet quality standards and are free from defects.

- Package Carefully package the finished panels to prevent damage during transportation.

Our Qingdao facility harnesses cutting-edge technology to produce Curved Greenhouse Glass Panels with unmatched precision. Our advanced equipment overcomes challenges like tight radii and large-scale designs, delivering customized, high-quality solutions for architectural, automotive, and restoration projects. Trust OrbGlass to bring your vision to life with expertise and innovation.

- 3 Advanced Flat and Curved Glass Tempering LinesProcess glass up to 3200mm x 5000mm, ensuring strength and safety for diverse applications.

- 2 Fully Automated Insulating Glass Production LinesProduce energy-efficient double/triple-glazed units, up to 3000mm x 4500mm, with ±0.2mm spacer accuracy.

- 1 High-Speed Double-Edge and 2 Four-Edge Grinding MachinesGrind edges at 6m/min with ±0.1mm precision, ensuring flawless finishes.

- 1 Precision Waterjet Cutting MachineCuts intricate shapes with ±0.5mm accuracy, supporting panels up to 4000mm x 6000mm.

- Advanced Flat and Curved Lamination EquipmentLaminates glass up to 3500mm x 5000mm with PVB interlayers for safety and UV protection.

Our advanced machinery ensures precision for ultra-small radius glass and oversized panels, meeting global standards (ISO 9001, CE). With continuous innovation and industry-standard contributions, OrbGlass delivers reliable, eco-friendly solutions.

Quality Control for Curved Greenhouse Glass Panels

we recognize that even the most advanced manufacturing equipment is only as reliable as the quality controls governing it. Curved glass demands millimeter-perfect precision, and defects like warping, micro-cracks, or inconsistent curvature can compromise structural integrity. Here’s how our 5-step quality assurance system eliminates risks at every stage:

-

Raw Material Inspection

Only use Grade A ultra-clear glass (iron content ≤0.015%) to prevent greenish tints. -

Pre-Production Calibration

3D-scanned bending molds must match CAD designs within ±0.1mm tolerance. -

In-Process Monitoring

Infrared thermal imaging detects heat distribution anomalies during tempering. -

Post-Production Testing

Laser scanners measure radius accuracy (±0.3mm) across 50+ data points.

Cost Structure of Curved Greenhouse Glass Panels

Curved greenhouse glass panels typically cost 2.60–3.50/sq.ft for glass or 1.65–3.00/sq.ft for polycarbonate, depending on thickness, coatings, and customization2611. While premium, OrbGlass offers competitive pricing through advanced manufacturing and direct B2B solutions. OrbGlass’s curved greenhouse glass panels are priced 20–40% below Western markets due to China’s streamlined production, minimized overheads, and economies of scale. Our ISO 9001-certified factory ensures high quality at lower costs

- Material TypeTempered ($2.60–$3.50), laminated ($3.00–$4.50), or polycarbonate ($1.65–$2.80) per sq.ft

- CustomizationRadius adjustments (+10–25%), thickness (4–19mm), and size (+5–15%)

- CoatingsUV-resistant (+$0.30–$0.80/sq.ft), low-E (+$0.50–$1.20/sq.ft)

- ShippingSea freight ($800–$2,500/container) or air (+$3.50–$6.50/kg)

- Import DutiesVaries by country (e.g., 3–8% in the EU, 5–15% in the US)

- InstallationLocal labor ($45–$150/hr) or DIY with our guides

- CertificationsCE, SGCC, or 3C compliance (+2–5%)

- After-SalesOptional 5–10-year warranty (+3–8% of order)

Frequently Asked Questions

What are curved greenhouse glass panels?

Curved greenhouse glass panels are bent glass sheets enhancing aesthetics, light diffusion, and structural strength in greenhouses. Typically tempered or laminated, they ensure durability and safety. OrbGlass crafts high-quality curved panels customized for your greenhouse needs.

What are the benefits of using curved glass in greenhouses?

Curved glass improves light diffusion, minimizes hotspots, and resists wind and snow loads effectively. It also adds a modern look. OrbGlass helps you select the perfect curved glass for superior greenhouse performance.

What types of glass are used in curved greenhouse panels?

Options include tempered glass for strength, laminated for safety, and insulated glass for energy efficiency. OrbGlass offers diverse glass types to meet your specific greenhouse requirements.

Are curved glass panels more expensive than flat ones?

Yes, due to specialized manufacturing, curved panels cost more. Their benefits in light and durability justify the price. OrbGlass provides cost-effective, tailored solutions to fit your budget.

Can curved glass panels be customized for specific designs?

Yes, they can be customized in curvature, size, and type to suit unique greenhouse designs. OrbGlass specializes in bespoke curved glass, ensuring a perfect fit for your project.

How do curved glass panels affect light diffusion?

Their curvature spreads light evenly, reducing shadows and promoting uniform plant growth. OrbGlass assists in choosing the ideal curvature for optimal light distribution.

What is the lifespan of curved greenhouse glass panels?

Properly maintained, they last decades, with tempered and laminated options being highly durable. OrbGlass ensures longevity with top-quality manufacturing standards.

How do I maintain and clean curved glass panels?

Clean regularly with mild soap and water, avoiding abrasives to prevent scratches. OrbGlass offers maintenance advice and services for pristine panel condition.

Are there energy-efficient options for curved glass panels?

Yes, Low-E coatings and insulated units reduce heat loss, enhancing efficiency. OrbGlass provides energy-saving curved glass to lower your greenhouse costs.

Can curved glass panels withstand harsh weather?

Tempered and laminated curved panels resist wind, hail, and snow effectively. OrbGlass manufactures weather-durable panels meeting global safety standards.

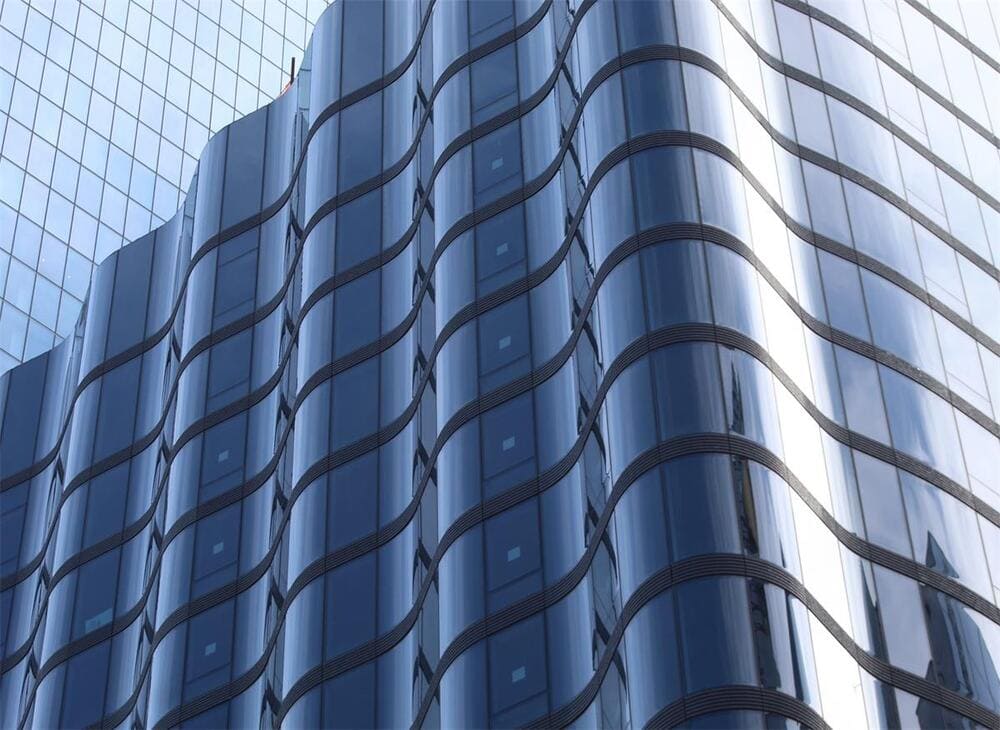

Curved Greenhouse Glass Panels Application Scenarios

Curved greenhouse glass panels are used in commercial agriculture, residential greenhouses, botanical conservatories, research facilities, and sustainable architecture. Their tempered/laminated options enhance durability, light diffusion, and thermal efficiency while resisting snow/wind loads. Custom curvatures adapt to modern designs, supporting eco-friendly and high-performance glazing solutions.

Commercial Agriculture Greenhouses

OrbGlass’s curved panels optimize light distribution in large-scale greenhouses, enhancing crop yields. Tempered or laminated glass withstands extreme weather, while custom radii ensure seamless integration with steel/aluminum frames. Ideal for year-round farming with UV protection and thermal insulation.

Botanical Conservatories & Public Gardens

Architecturally striking curved glass roofs create visually immersive environments. Laminated options ensure structural integrity for wide-span designs, while UV-filtering coatings protect delicate plants and reduce glare for visitors.

Residential Lean-To Greenhouses

Space-saving curved eaves made from tempered glass blend aesthetics and safety. Customizable sizes fit urban gardens, offering durability against impacts and wind. Energy-efficient coatings reduce heat loss, ideal for compact, modern homes.

We Are Always Provide Best Curved Greenhouse Glass Panels For Your Project

Hear From Our Clients

We believe in creating long-term partnerships based on trust and quality. See what our clients say about working with us.

Curved Greenhouse Glass Panels Related Articles

What Is Curved Glass Called? (Complete Guide to Types)

2025-09-12

Top 9 Curved Glass Manufacturers Brazilian

2025-07-22

Top 9 Curved Glass Manufacturers in UAE 2025

2025-07-12

Top 8 Curved Glass Manufacturers South Africa 2025

2025-05-07

Top 7 Curved Glass Manufacturers Indian 2025

2025-05-07

Top 9 Curved Glass Manufacturers Australian 2025

2025-05-08

Top 10 Curved Glass Manufacturers UK 2025

2025-05-07

Top 10 Curved Glass Manufacturers USA 2025

2025-05-07

Top 10 Curved Glass Manufacturers 2025

2025-05-07

Get Started with OrbGlass Today!

Aerospace-grade CNC machines carve brass frames with micron-level accuracy, while AI vision systems inspect crystal cuts for refractive consistency. Even hidden parts undergo stress tests mimicking 10+ years of use.

- Material Traceability

Each brass sheet or crystal slab has a QR code linking to its origin and metallurgical report. - Self-Correcting Production

IoT-enabled machines adjust cutting paths in real time if material thickness varies. - Durability Validated

Salt spray chambers test finishes against humidity levels from Dubai villas to Nordic churches.