Curved Glass Shower Doors

Curved glass shower doors are tempered or laminated glass panels bent into elegant arcs, offering modern aesthetics and space efficiency. Ideal for bathrooms, they enhance safety, durability, and design flexibility. These doors are customizable in curvature, thickness, and coatings, making them perfect for residential and commercial upgrades.

Since 2015, OrbGlass, based in Qingdao, China, has specialized in crafting premium curved glass solutions. With 9+ years of expertise, we produce tempered, laminated, and composite curved glass for shower enclosures, architectural facades, and industrial displays. Our advanced facilities and global certifications ensure tailored, high-performance products that meet diverse project needs. Trust us for precision-engineered, eco-friendly solutions.

What Are the Different Types of Curved Glass Shower Doors

Curved glass shower doors come in multiple types, including semi-circular, quadrant, full-round, sliding, and pivot-hinged designs. These doors feature tempered, laminated, or composite curved glass for safety and durability. Popular configurations address space optimization, modern aesthetics, and seamless integration with shower bases or enclosures.

Type of Curved Glass Shower Doors

We specialize in manufacturing all types of curved glass shower doors, tailored to your exact specifications. With 9+ years of expertise in custom curved glass solutions, our advanced facility in Qingdao, China, delivers precision-engineered products for global clients. From radius adjustments to specialized coatings, we solve complex design challenges while adhering to international certifications (ISO 9001, CE, SGCC).

- Semi-Circular Shower Doors Ideal for corner installations, these 90-degree curved doors maximize space efficiency while offering a sleek, modern look. Compatible with tempered or laminated glass for safety.

- Full-Round Shower Doors 360-degree curved glass panels for freestanding showers. Supports ultra-clear, frosted, or tinted glass with optional anti-slip coatings.

- Sliding Curved Doors Frameless or semi-frameless systems with smooth rollers. Ideal for alcove showers, available in brushed nickel, black matte, or stainless steel finishes.

- Pivot-Hinged Curved Doors Luxury inward/outward swinging doors with adjustable hinges. Supports large-radius curves (up to 1.5m) and laminated safety glass.

- Custom Radius Doors Bespoke curvatures (5°–180°) for unique layouts. Engineered with composite glass for structural integrity in oversized designs.

Our Services for Curved Glass Shower Doors

OrbGlass provides end-to-end B2B solutions for curved glass shower doors, including custom design, precision bending, tempered/laminated glass production, and bulk manufacturing. We handle complex geometries (small radii, large arcs) and offer tailored thickness (6-19mm), coatings (UV protection, energy-efficient), and global certifications (CE, SGCC, 3C). Partner with us for OEM/ODM projects, technical support, and seamless logistics for wholesale orders.

- Precision

- Certifications

- Scalability

- Durability

- Innovation

The Manufacturing Process of Curved Glass Shower Doors

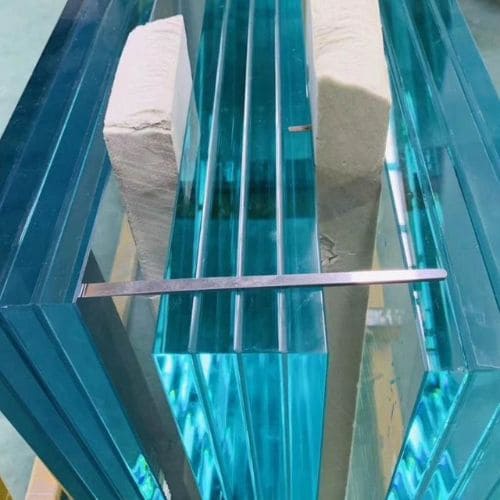

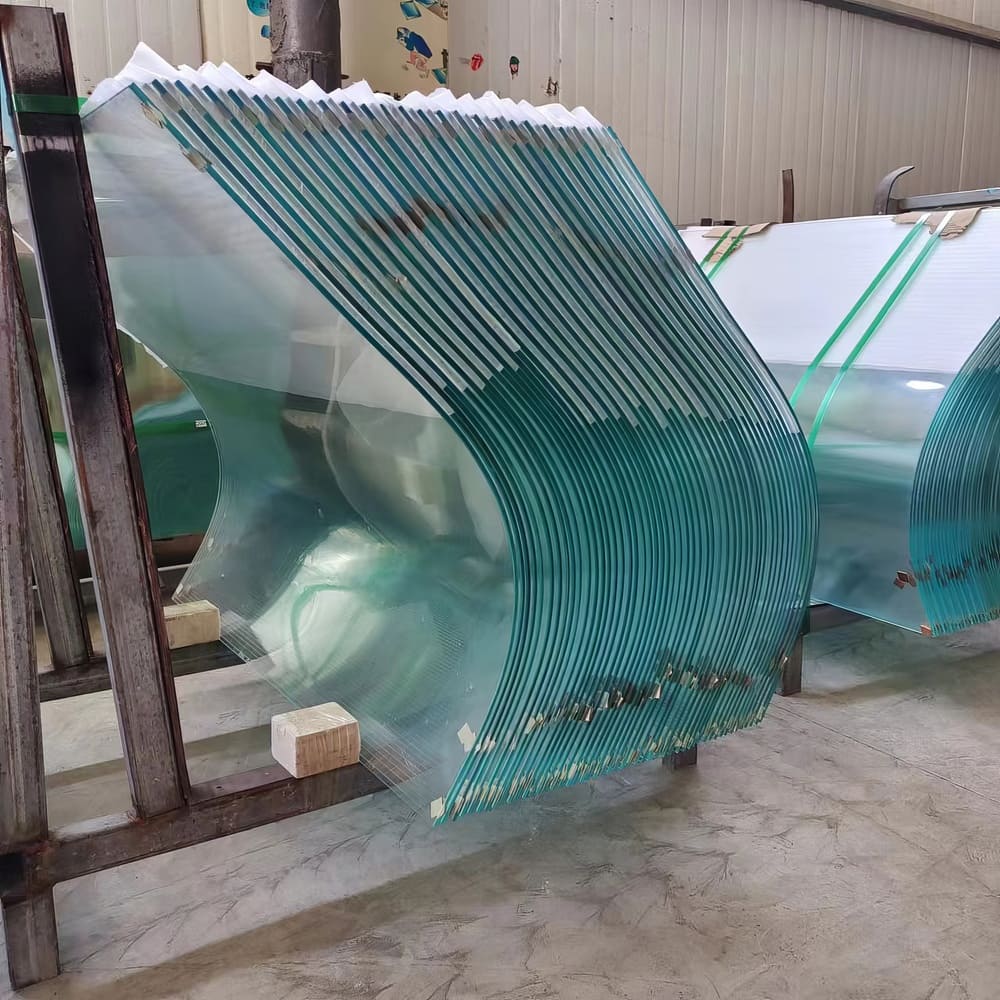

Curved glass shower doors are manufactured through precision heating, bending, and tempering/laminating processes. Advanced techniques like CNC cutting, mold-based curvature forming, and edge polishing ensure safety (EN 14449/ANSI Z97.1 compliance), while customization options include radius adjustments (5°–180°), thickness (6–12mm), and glass types (tempered, laminated, composite).

- Design & Prototyping CAD-based curvature simulation and mold creation for precise radius (5°–180°).

- Glass Cutting CNC or waterjet cutting of raw glass to exact dimensions (±0.5mm tolerance).

- Edge Grinding High-speed磨边机s polish edges to 45°–60° bevels for safety and aesthetics.

- Heat Bending Glass heated to 600–700°C in electric furnaces, shaped using custom molds.

- Tempering/Laminating Rapid cooling for tempered glass (650–700 MPa strength) or PVB interlayer bonding for laminated glass.

- Quality Inspection Stress tests, thickness verification, and optical distortion checks per ISO 9001 standards.

- Packaging Foam-protected crating with anti-scratch film for global shipping.

Our Qingdao facility harnesses cutting-edge technology to produce Curved Glass Shower Doors with unmatched precision. Our advanced equipment overcomes challenges like tight radii and large-scale designs, delivering customized, high-quality solutions for architectural, automotive, and restoration projects. Trust OrbGlass to bring your vision to life with expertise and innovation.

- 3 Advanced Flat and Curved Glass Tempering LinesProcess glass up to 3200mm x 5000mm, ensuring strength and safety for diverse applications.

- 2 Fully Automated Insulating Glass Production LinesProduce energy-efficient double/triple-glazed units, up to 3000mm x 4500mm, with ±0.2mm spacer accuracy.

- 1 High-Speed Double-Edge and 2 Four-Edge Grinding MachinesGrind edges at 6m/min with ±0.1mm precision, ensuring flawless finishes.

- 1 Precision Waterjet Cutting MachineCuts intricate shapes with ±0.5mm accuracy, supporting panels up to 4000mm x 6000mm.

- Advanced Flat and Curved Lamination EquipmentLaminates glass up to 3500mm x 5000mm with PVB interlayers for safety and UV protection.

Our advanced machinery ensures precision for ultra-small radius glass and oversized panels, meeting global standards (ISO 9001, CE). With continuous innovation and industry-standard contributions, OrbGlass delivers reliable, eco-friendly solutions.

Quality Control for Curved Glass Shower Doors

we recognize that even the most advanced manufacturing equipment is only as reliable as the quality controls governing it. Curved glass demands millimeter-perfect precision, and defects like warping, micro-cracks, or inconsistent curvature can compromise structural integrity. Here’s how our 5-step quality assurance system eliminates risks at every stage:

-

Raw Material Inspection

Only use Grade A ultra-clear glass (iron content ≤0.015%) to prevent greenish tints. -

Pre-Production Calibration

3D-scanned bending molds must match CAD designs within ±0.1mm tolerance. -

In-Process Monitoring

Infrared thermal imaging detects heat distribution anomalies during tempering. -

Post-Production Testing

Laser scanners measure radius accuracy (±0.3mm) across 50+ data points.

Cost Structure of Curved Glass Shower Doors

Curved glass shower doors typically cost 300–2,800+ in Western markets due to high material, energy, and labor costs13. However, OrbGlass offers B2B wholesale pricing 30–50% lower by leveraging advanced manufacturing and localized material sourcing in China. While curved shower doors are premium-priced globally, OrbGlass provides cost-effective solutions for bulk orders. Our direct factory production eliminates middlemen, and strategic logistics from Qingdao reduce shipping expenses, ensuring significant savings compared to local suppliers

- Material CostsIncludes tempered/laminated glass, coatings, and hardware (e.g., stainless steel handles).

- Customization & ProductionPrecision bending, edge polishing, and thickness adjustments (6–19mm).

- Certification ComplianceCE, SGCC, 3C, and ISO 9001 certification fees.

- Shipping & LogisticsSea/air freight, insurance, and port handling.

- Import Duties & TaxesVaries by destination country (e.g., 5–15% in the US/EU).

- Installation SupportOptional technical guides or on-site assistance.

- Inventory BufferExtra units for potential transit damage or defects.

- After-Sales ServiceWarranty claims and replacement logistics.

.

Frequently Asked Questions

What are the disadvantages of pivot shower doors?

Pivot shower doors require more clearance space for swinging and may leak if not aligned properly. They also demand precise installation. OrbGlass offers precision-engineered pivot hinges and custom sealing solutions to minimize these issues, ensuring leak-free performance and smooth operation.

How do I measure a curved shower door?

Measure the radius, height, and arc length of your shower base or enclosure. Use a flexible tape for curvature accuracy. OrbGlass provides CAD-guided measurement templates and expert support to ensure perfect-fit curved doors, eliminating installation errors.

Can curved shower doors be customized?

Yes, OrbGlass customizes curved shower doors in radii (5°–180°), thickness (6–12mm), glass types (tempered, laminated), and finishes (matte, frosted). Our ISO 9001-certified process ensures precision for unique bathroom layouts.

Why won’t my curved shower door stay closed?

Misaligned rollers, worn hinges, or improper curvature calibration often cause this. OrbGlass supplies adjustable stainless steel hinges and roller systems with ±0.5mm tolerance for seamless closure. We also offer troubleshooting guides.

Are curved shower doors safe?

Yes, when made with tempered (650–700 MPa strength) or laminated glass (PVB interlayer). OrbGlass doors meet ANSI Z97.1 and EN 14449 safety standards, ensuring shatter resistance and durability.

What’s the cost of curved glass shower doors?

Costs range from $300–$2,000+ based on size, glass type, and customization. OrbGlass provides competitive B2B pricing for bulk orders, with volume discounts and 15–25-day lead times.

How to maintain curved shower doors?

Use pH-neutral cleaners and soft cloths to avoid scratches. OrbGlass offers hydrophobic nano-coatings (optional) to repel water and reduce mineral buildup, simplifying maintenance.

Which is better: pivot or sliding curved doors?

Sliding doors save space, while pivots offer wider access. OrbGlass designs both types with reinforced aluminum frames and adjustable systems, tailored to your bathroom’s layout and traffic flow.

Do curved doors work for small bathrooms?

Yes, quadrant (¼-circle) or semi-circular designs maximize space efficiency. OrbGlass engineers compact curved doors as narrow as 32” with 6mm tempered glass for safety in tight spaces.

How long does installation take?

Professional installation takes 2–4 hours, depending on complexity. OrbGlass ships pre-drilled doors with numbered components and step-by-step guides to streamline the process.

Curved Glass Shower Doors Application Scenarios

Curved glass shower doors are ideal for modern bathrooms, luxury hotels, spa facilities, and compact spaces. Their smooth arcs enhance accessibility, maximize space efficiency, and add sleek aesthetics. Customizable in thickness (6–19mm), coatings, and safety features, they suit residential, commercial, and hospitality projects globally.

Residential Bathrooms

Curved shower doors optimize small bathrooms by reducing sharp edges and creating fluid layouts. Tempered glass ensures safety, while customizable radii (100–3000mm) fit unique shower bases. Ideal for modern homes seeking space-saving, ADA-compliant designs.

Healthcare Facilities

Hygienic, easy-to-clean curved glass doors meet strict sanitation standards in hospitals and clinics. Laminated glass options enhance safety, while radius customization ensures compatibility with accessible shower layouts for patients.

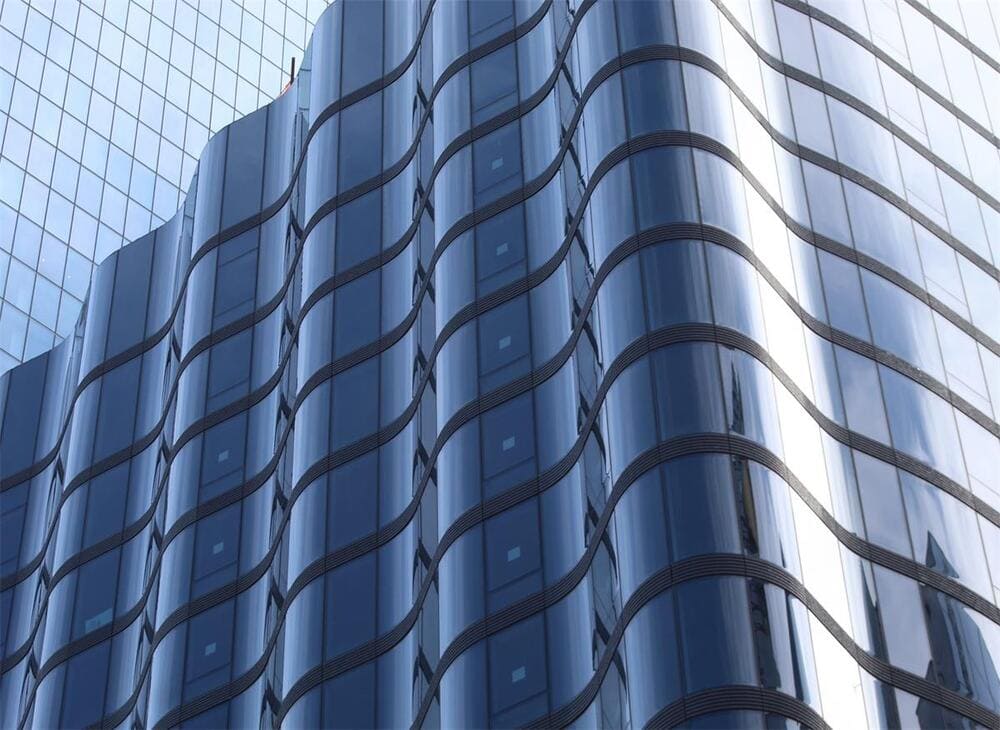

Luxury Hotels & Resorts

Elevate guest experiences with frameless curved glass enclosures. Their seamless design pairs with energy-efficient coatings to reduce maintenance. Perfect for high-end suites, offering durability and visual elegance that aligns with 5-star aesthetics.

We Are Always Provide Best Curved Glass Shower Doors For Your Project

Hear From Our Clients

We believe in creating long-term partnerships based on trust and quality. See what our clients say about working with us.

Curved Glass Shower Doors Related Articles

What Is Curved Glass Called? (Complete Guide to Types)

2025-09-12

Top 9 Curved Glass Manufacturers Brazilian

2025-07-22

Top 9 Curved Glass Manufacturers in UAE 2025

2025-07-12

Top 8 Curved Glass Manufacturers South Africa 2025

2025-05-07

Top 7 Curved Glass Manufacturers Indian 2025

2025-05-07

Top 9 Curved Glass Manufacturers Australian 2025

2025-05-08

Top 10 Curved Glass Manufacturers UK 2025

2025-05-07

Top 10 Curved Glass Manufacturers USA 2025

2025-05-07

Top 10 Curved Glass Manufacturers 2025

2025-05-07

Get Started with OrbGlass Today!

Aerospace-grade CNC machines carve brass frames with micron-level accuracy, while AI vision systems inspect crystal cuts for refractive consistency. Even hidden parts undergo stress tests mimicking 10+ years of use.

- Material Traceability

Each brass sheet or crystal slab has a QR code linking to its origin and metallurgical report. - Self-Correcting Production

IoT-enabled machines adjust cutting paths in real time if material thickness varies. - Durability Validated

Salt spray chambers test finishes against humidity levels from Dubai villas to Nordic churches.