Curved Glass Railings

Curved glass railings, also known as bent glass balustrades, are stylish safety barriers made from bent glass panels. They are commonly used in staircases, balconies, and terraces to provide both safety and a modern aesthetic. While costs can vary, they are a valuable addition to any property.

OrbGlass, a leading curved glass manufacturer since 2015, provides customized solutions for global clients. Our products, including tempered, laminated, and composite curved glass, are used in staircases, balconies, and facades. We help clients navigate procurement challenges with our expertise and commitment to quality.

What Are the Different Types of Curved Glass Railings

Curved glass railings come in various types, including tempered glass railings for enhanced durability, laminated glass railings for superior safety, frameless designs for a modern aesthetic, posted railings for added support, spiral railings for unique staircase applications, and fully custom options to meet specific design needs. Each type is engineered to provide both functionality and style, making them ideal for a range of architectural projects.

Type of Curved Glass Railings

- Tempered Curved Glass Railings Made from heat-treated tempered glass, these railings offer exceptional strength and resistance to breakage, making them perfect for high-traffic areas or where safety is paramount.

- Laminated Curved Glass Railings Featuring multiple layers of glass bonded with a plastic interlayer, laminated railings provide enhanced safety by holding together even if shattered. They are ideal for applications requiring both security and aesthetic appeal.

- Frameless Curved Glass Railings These railings appear to float with minimal visible hardware, offering a sleek, modern look that enhances any space while maintaining safety and durability.

- Posted Curved Glass Railings With vertical posts supporting the curved glass panels, these railings combine strength with visibility, available in various materials to complement different design styles.

- Spiral Curved Glass Railings Designed specifically for spiral staircases, these railings follow a helical curve, adding both functionality and a striking visual element to staircase designs.

- Custom Curved Glass Railings Tailored to your exact specifications, our custom railings can be bent to any radius or shape, allowing for unlimited creativity in architectural design.

Our Services for Curved Glass Railings

we provide comprehensive services for Curved Glass Railings, including custom design and precision manufacturing tailored to your project’s specifications. Our expertise spans tempered, laminated, and composite curved glass, ensuring the perfect fit for architectural and industrial applications. We offer technical consultation to guide you through the selection process and guarantee seamless integration. With our advanced facilities and commitment to quality, we handle large-scale orders efficiently, delivering innovative, safe, and aesthetically superior railing solutions worldwide.

-

Tailored Designs

-

Precise Curvature

-

Diverse Glass Options

-

Innovative Solutions

-

Global Delivery

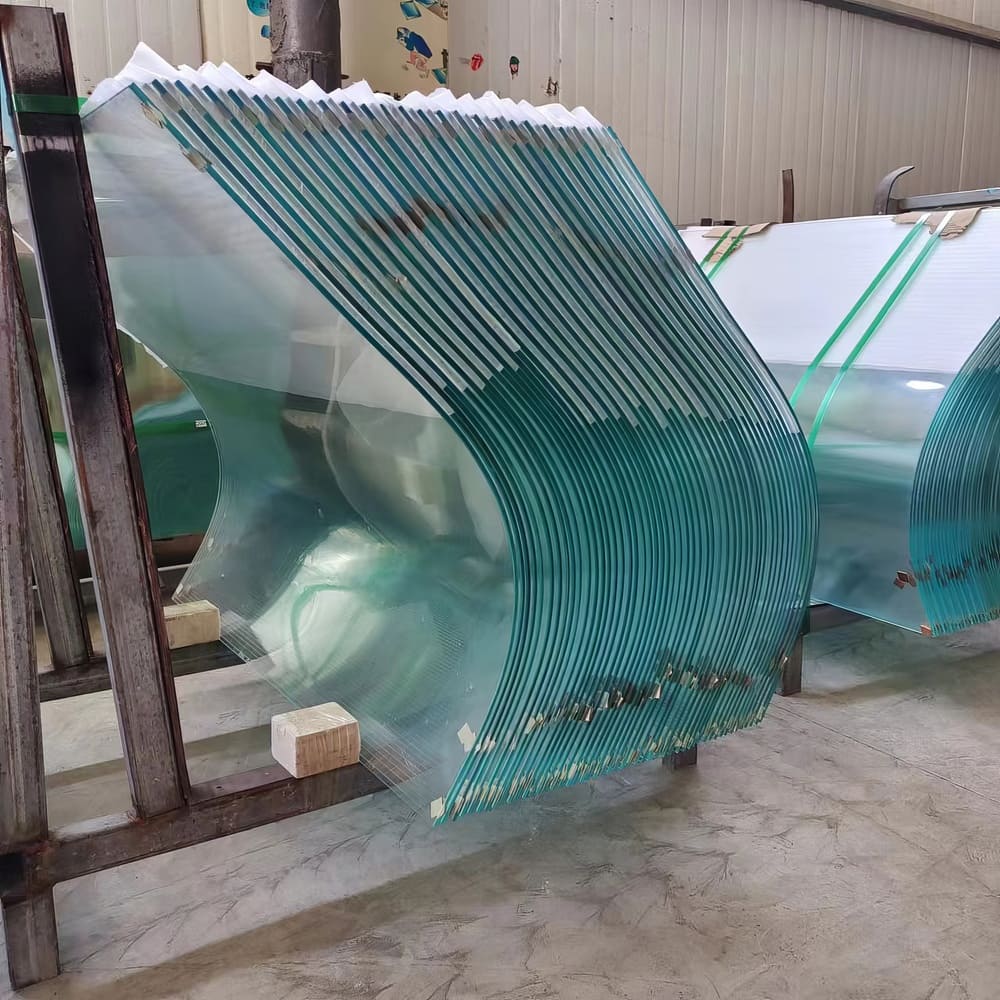

The Manufacturing Process of Curved Glass Railings

- Design and Planning Engineers design the curvature and dimensions to meet client specifications.

- Glass Selection High-quality tempered or laminated glass is chosen for durability.

- Cutting Precision water jet machines cut glass to exact sizes.

- Heating and Bending Glass is heated and bent using advanced furnaces.

- Tempering or Laminating Glass is tempered or laminated for strength and safety.

- Quality Control Panels are tested to meet ISO 9001 and CE standards.

Our Qingdao facility harnesses cutting-edge technology to produce Curved Glass Railings with unmatched precision. Our advanced equipment overcomes challenges like tight radii and large-scale designs, delivering customized, high-quality solutions for architectural, automotive, and restoration projects. Trust OrbGlass to bring your vision to life with expertise and innovation.

- 3 Advanced Flat and Curved Glass Tempering LinesProcess glass up to 3200mm x 5000mm, ensuring strength and safety for diverse applications.

- 2 Fully Automated Insulating Glass Production LinesProduce energy-efficient double/triple-glazed units, up to 3000mm x 4500mm, with ±0.2mm spacer accuracy.

- 1 High-Speed Double-Edge and 2 Four-Edge Grinding MachinesGrind edges at 6m/min with ±0.1mm precision, ensuring flawless finishes.

- 1 Precision Waterjet Cutting MachineCuts intricate shapes with ±0.5mm accuracy, supporting panels up to 4000mm x 6000mm.

- Advanced Flat and Curved Lamination EquipmentLaminates glass up to 3500mm x 5000mm with PVB interlayers for safety and UV protection.

Our advanced machinery ensures precision for ultra-small radius glass and oversized panels, meeting global standards (ISO 9001, CE). With continuous innovation and industry-standard contributions, OrbGlass delivers reliable, eco-friendly solutions.

Quality Control for Curved Glass Railings

we recognize that even the most advanced manufacturing equipment is only as reliable as the quality controls governing it. Curved glass demands millimeter-perfect precision, and defects like warping, micro-cracks, or inconsistent curvature can compromise structural integrity. Here’s how our 5-step quality assurance system eliminates risks at every stage:

-

Raw Material Inspection

Only use Grade A ultra-clear glass (iron content ≤0.015%) to prevent greenish tints. -

Pre-Production Calibration

3D-scanned bending molds must match CAD designs within ±0.1mm tolerance. -

In-Process Monitoring

Infrared thermal imaging detects heat distribution anomalies during tempering. -

Post-Production Testing

Laser scanners measure radius accuracy (±0.3mm) across 50+ data points.

Cost Structure of Curved Glass Railings

Curved glass railings are generally more expensive than standard railings due to the complex manufacturing process and specialized materials required. Prices vary based on glass type, curvature, and customization. However, OrbGlass offers competitive pricing through advanced manufacturing and economies of scale. Although curved glass railings tend to be pricier in the market, OrbGlass provides them at significantly lower costs than local markets. Our direct manufacturing, efficient production, and strategic material sourcing from Qingdao, China, ensure affordability without compromising quality.

- Material CostsVaries by type: tempered (8–12mm), laminated (PVB/SGP interlayer), or composite (Low-E coatings), accounting for 30–40% of total expenses.

- Customization FeesDesign adjustments (radius <175mm, thickness >19mm) or special coatings (UV/thermal) incur 5–15% surcharges.

- Production CostsIncludes energy (20–30%), labor (5–10%), and equipment depreciation (10–20%) for bending, tempering, and polishing.

- Shipping & LogisticsFOB Qingdao port rates: ~$1,800–$5,800/container (40HQ) to EU/US, with anti-breakage packaging (wooden crates + foam).

- Import Duties/TaxesVaries by country (e.g., 6–12% in EU, 3–10% in USA). OrbGlass provides HS codes and compliance documents to streamline clearance.

- Installation SupportOptional on-site technical guidance ($150–$300/day) for complex projects (e.g., structural glazed railings).

- Compliance TestingThird-party certification fees (e.g., ANSI Z97.1, EN 12600 impact tests): $500–$2,000 per batch.

- After-Sales Warranty5-year warranty against defects: 1–3% of order value, covering delamination, stress cracks, or coating failures.

Frequently Asked Questions

Is curved glass expensive?

Curved glass costs more than flat glass due to its complex heating and bending process. Prices depend on size and customization. OrbGlass offers competitive pricing for premium curved glass railings, delivering value. Contact us for a tailored quote.

What is a curved railing called?

A curved railing is known as a “bent glass railing” or “curved glass balustrade,” emphasizing its unique design. OrbGlass specializes in these systems, providing expert design and installation support.

How much does a glass railing cost?

Glass railing costs range from $150 to $600 per linear foot, based on glass type and design complexity. OrbGlass offers cost-effective solutions and expert budgeting advice for your project.

Are glass railings worth it?

Glass railings offer modern style, durability, and unobstructed views, making them a worthwhile investment. OrbGlass ensures quality installation and maintenance tips to maximize your railing’s benefits.

Does glass railing increase home value?

Yes, glass railings boost home value with their contemporary appeal, especially in luxury homes. OrbGlass helps you select designs that enhance your property’s marketability.

Are curved glass railings safe?

Curved glass railings are safe when made with tempered or laminated glass, resisting impact and shattering. OrbGlass guarantees safety-compliant products for your peace of mind.

Can curved glass railings be customized?

Yes, curved glass railings can be customized in size, curvature, and finish to suit your design. OrbGlass provides bespoke solutions tailored to your specifications.

How do I maintain curved glass railings?

Clean curved glass railings with mild soap and a soft cloth to remove smudges. OrbGlass offers maintenance guidance and products to keep them pristine.

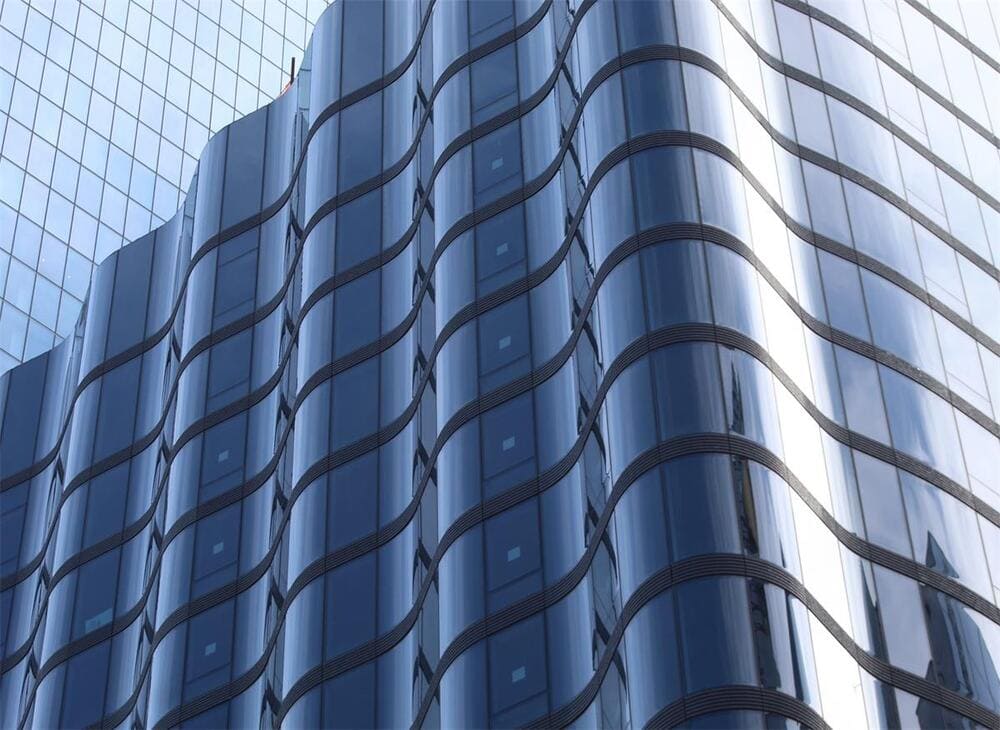

Curved Glass Railings Application Scenarios

Curved Glass Railings from OrbGlass are versatile, enhancing staircases, balconies, and terraces with safety and modern style. Ideal for commercial spaces and residential homes, they offer a sleek, transparent look, boosting aesthetic appeal and architectural design.

Staircases

Curved glass railings elevate staircases, especially spiral designs, with a safe, unobstructed view. Their sleek style enhances modern homes, allowing light flow. Customizable by OrbGlass, they fit any shape, ensuring durability and elegance.

Commercial Spaces

In offices or retail settings, curved glass railings craft a modern, spacious feel. Used as barriers or partitions, they enhance interiors with sophistication. OrbGlass delivers transparency and strength for professional environments.

Balconies

For balconies, curved glass railings provide safety with clear views. Perfect for residential or commercial use, they add sophistication. OrbGlass ensures durability and low maintenance, making them ideal for stylish outdoor spaces.

We Are Always Provide Best Curved Glass Railings For Your Project

Hear From Our Clients

We believe in creating long-term partnerships based on trust and quality. See what our clients say about working with us.

Curved Glass Railings Related Articles

What Is Curved Glass Called? (Complete Guide to Types)

2025-09-12

Top 9 Curved Glass Manufacturers Brazilian

2025-07-22

Top 9 Curved Glass Manufacturers in UAE 2025

2025-07-12

Top 8 Curved Glass Manufacturers South Africa 2025

2025-05-07

Top 7 Curved Glass Manufacturers Indian 2025

2025-05-07

Top 9 Curved Glass Manufacturers Australian 2025

2025-05-08

Top 10 Curved Glass Manufacturers UK 2025

2025-05-07

Top 10 Curved Glass Manufacturers USA 2025

2025-05-07

Top 10 Curved Glass Manufacturers 2025

2025-05-07

Get Started with OrbGlass Today!

Aerospace-grade CNC machines carve brass frames with micron-level accuracy, while AI vision systems inspect crystal cuts for refractive consistency. Even hidden parts undergo stress tests mimicking 10+ years of use.

- Material Traceability

Each brass sheet or crystal slab has a QR code linking to its origin and metallurgical report. - Self-Correcting Production

IoT-enabled machines adjust cutting paths in real time if material thickness varies. - Durability Validated

Salt spray chambers test finishes against humidity levels from Dubai villas to Nordic churches.