Sliding Curved Glass Doors

Sliding curved glass doors are innovative architectural solutions combining sleek curvature with sliding functionality. Ideal for modern spaces, they maximize natural light, enhance aesthetics, and optimize space efficiency. Made from tempered, laminated, or insulated glass, these doors offer durability, safety, and energy efficiency for residential, commercial, and industrial applications.

With over 9 years of expertise, OrbGlass, based in Qingdao, China, specializes in custom sliding curved glass doors tailored to global clients. Our advanced facilities produce tempered, laminated, and composite curved glass solutions for skyscrapers, luxury interiors, high-tech displays, and industrial installations. Trust our precision engineering to elevate your project’s design and functionality.

What Are the Different Types of Sliding Curved Glass Doors

Sliding curved glass doors come in multiple types, including semi-circular, full-circle, and radius corner designs, with variations like frameless, automatic, and multi-panel systems. These doors use tempered, laminated, or insulated curved glass for durability, safety, and energy efficiency, serving residential, commercial, and industrial spaces.

Type of Sliding Curved Glass Doors

We’ve engineered every type of sliding curved glass door since 2015. From sleek frameless systems to heavy-duty industrial installations, our custom solutions address complex architectural needs. Partner with us for precision-curved glass doors tailored to your project’s specifications, backed by ISO 9001 and global safety certifications.

- Semi-Circular Sliding Doors Ideal for curved facades or patios, offering smooth operation with a 180° arc design.

- Full-Circle Rotating Systems Motorized or manual 360° sliding doors for grand entrances or futuristic interiors.

- Radius Corner Sliding Doors Seamless 90° curved transitions, perfect for connecting indoor/outdoor spaces.

- Frameless Curved Sliders Minimalist designs with hidden tracks, suited for modern showers or luxury interiors.

- Automatic Curved Doors Sensor-operated systems for high-traffic commercial or hospitality applications.

- Multi-Panel Curved Walls Expandable configurations for large openings, using tempered or laminated curved glass.

- Insulated Curved Sliders Double-glazed units with thermal breaks for energy-efficient buildings.

Our Services for Sliding Curved Glass Doors

OrbGlass provides end-to-end solutions for sliding curved glass doors, from precision engineering to global logistics. We offer full customization of curvature (5°–180°), glass types (tempered, laminated, composite), and coatings (low-E, UV protection). Our services include technical drawings, prototyping, ISO-certified production, and door system integration (automatic tracks, hidden frames). With 24/7 project support and door sizes up to 12m x 3m, we ensure seamless delivery to architects, contractors, and distributors worldwide.

- Precision-Crafted

- Globally Certified

- Full Customization

- Patented Tech

- Fast Delivery

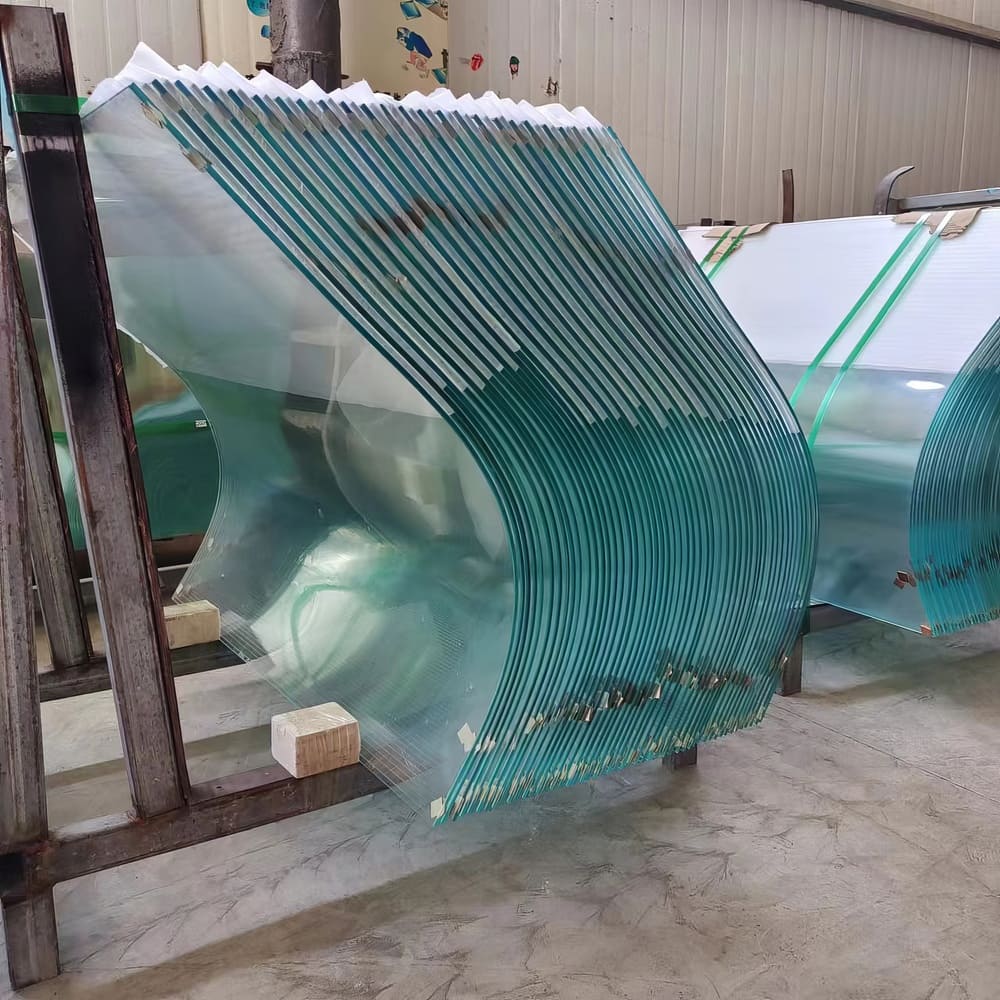

The Manufacturing Process of Sliding Curved Glass Doors

Sliding curved glass doors are crafted through precision glass cutting, thermal bending (150-650°C), tempering/laminating for safety, edge polishing, track system integration, and quality testing (ISO 9001/CE). OrbGlass uses CNC waterjet cutting and patented heat-forming tech to create radiuses as tight as 500mm, ensuring durability and seamless operation.

- Design & Prototyping CAD modeling and 3D mockups for curvature validation.

- CNC Waterjet Cutting Precision cutting of raw glass to specified dimensions.

- Thermal Bending Heating in kilns (500-650°C) to achieve 5°–180° curves.

- Tempering/Laminating Strengthening via rapid cooling or PVB interlayer fusion.

- Edge Polishing High-speed grinding for smooth, safe edges.

- Track Integration Installing custom sliding mechanisms (manual/automatic).

- Quality Control Stress tests, optical clarity checks, and load certification.

Our Qingdao facility harnesses cutting-edge technology to produce Sliding Curved Glass Doors with unmatched precision. Our advanced equipment overcomes challenges like tight radii and large-scale designs, delivering customized, high-quality solutions for architectural, automotive, and restoration projects. Trust OrbGlass to bring your vision to life with expertise and innovation.

- 3 Advanced Flat and Curved Glass Tempering LinesProcess glass up to 3200mm x 5000mm, ensuring strength and safety for diverse applications.

- 2 Fully Automated Insulating Glass Production LinesProduce energy-efficient double/triple-glazed units, up to 3000mm x 4500mm, with ±0.2mm spacer accuracy.

- 1 High-Speed Double-Edge and 2 Four-Edge Grinding MachinesGrind edges at 6m/min with ±0.1mm precision, ensuring flawless finishes.

- 1 Precision Waterjet Cutting MachineCuts intricate shapes with ±0.5mm accuracy, supporting panels up to 4000mm x 6000mm.

- Advanced Flat and Curved Lamination EquipmentLaminates glass up to 3500mm x 5000mm with PVB interlayers for safety and UV protection.

Our advanced machinery ensures precision for ultra-small radius glass and oversized panels, meeting global standards (ISO 9001, CE). With continuous innovation and industry-standard contributions, OrbGlass delivers reliable, eco-friendly solutions.

Quality Control for Sliding Curved Glass Doors

we recognize that even the most advanced manufacturing equipment is only as reliable as the quality controls governing it. Curved glass demands millimeter-perfect precision, and defects like warping, micro-cracks, or inconsistent curvature can compromise structural integrity. Here’s how our 5-step quality assurance system eliminates risks at every stage:

-

Raw Material Inspection

Only use Grade A ultra-clear glass (iron content ≤0.015%) to prevent greenish tints. -

Pre-Production Calibration

3D-scanned bending molds must match CAD designs within ±0.1mm tolerance. -

In-Process Monitoring

Infrared thermal imaging detects heat distribution anomalies during tempering. -

Post-Production Testing

Laser scanners measure radius accuracy (±0.3mm) across 50+ data points.

Cost Structure of Sliding Curved Glass Doors

Sliding curved glass doors typically range from1,200to6,500+ due to custom curvature, specialized glass (tempered/laminated), and track systems, but offer long-term value through energy efficiency, durability, and architectural appeal. Our direct factory pricing in Qingdao, China, cuts costs by 30–50% compared to Western markets, leveraging advanced automation, bulk material procurement, and streamlined logistics for global B2B clients

- Custom Design & EngineeringIncludes CAD modeling, curvature prototyping, and structural analysis.

- Material CostsTempered/laminated glass (30–40%), aluminum/steel frames (20–25%), and energy-efficient coatings.:cite[1]:cite[3]

- Manufacturing & LaborCNC cutting, thermal bending (500–650°C), and ISO-certified assembly.:cite[7]

- Certification & TestingCE, SGCC, and 3C compliance for safety and export.

- Packaging & ShippingCrated transport with shockproof materials and global logistics (5–10% of total).:cite[1]:cite[9]

- Import Duties & TaxesVaries by region (e.g., 2–15% in the US/EU).:cite[8]

- Installation SupportOptional technical guidance or on-site team fees.

- MaintenanceLifetime warranty on glass, 10-year track system coverage.

Frequently Asked Questions

Are sliding curved glass doors expensive?

Sliding curved glass doors typically cost between $1,200–$6,500+, depending on size, curvature complexity, and glass type. OrbGlass offers direct factory pricing, reducing costs by 30–50% compared to local suppliers, with bulk order discounts available. We provide transparent quotes tailored to your project’s specifications.

Can sliding curved doors be automated?

Yes, sliding curved doors can integrate motorized systems for touchless operation. OrbGlass supplies sensor-activated or remote-controlled automation compatible with curved tracks, ideal for commercial or high-end residential projects. We engineer seamless integration for smooth functionality.

What glass types are used for curved sliding doors?

Tempered, laminated, or insulated glass are standard for safety and durability. OrbGlass offers optional low-E coatings, UV protection, and acoustic interlayers. Our ISO-certified production ensures flawless curvature and impact resistance.

How long do sliding curved glass doors last?

Properly maintained sliding curved glass doors last 20–30 years. OrbGlass uses reinforced aluminum/steel tracks and corrosion-resistant hardware. We provide a 10-year warranty on mechanisms and lifetime glass breakage coverage.

Are curved sliding doors energy-efficient?

Yes, with thermal-break frames and double-glazed glass, they reduce heat transfer by up to 40%. OrbGlass offers ENERGY STAR®-compliant options, lowering HVAC costs for commercial/residential spaces.

Can curved sliding doors fit non-standard openings?

Absolutely. OrbGlass specializes in custom radii (5°–180°), heights up to 10m, and widths exceeding 12m. Our engineers validate designs via 3D prototyping to ensure precise fitment for unique architectural needs.

How are curved sliding doors installed?

Installation requires precision alignment of curved tracks and load-bearing supports. OrbGlass provides detailed manuals, video guides, or on-site technician support for complex projects, ensuring hassle-free setup.

Do curved sliding doors require special maintenance?

Routine cleaning and track lubrication suffice. OrbGlass uses scratch-resistant glass and stainless-steel rollers. We supply maintenance kits and prioritize durable materials to minimize upkeep costs.

What safety certifications do curved sliding doors have?

OrbGlass doors meet CE, ANSI, and 3C standards for impact resistance and fire safety. Our laminated glass holds EN 12600 certification, ideal for public spaces requiring high-security glazing.

Can I get curved sliding doors for coastal areas?

Yes. OrbGlass uses marine-grade aluminum and anti-corrosion coatings for saltwater environments. We tailor solutions for coastal resilience, including reinforced seals against humidity and storms.

Sliding Curved Glass Doors Application Scenarios

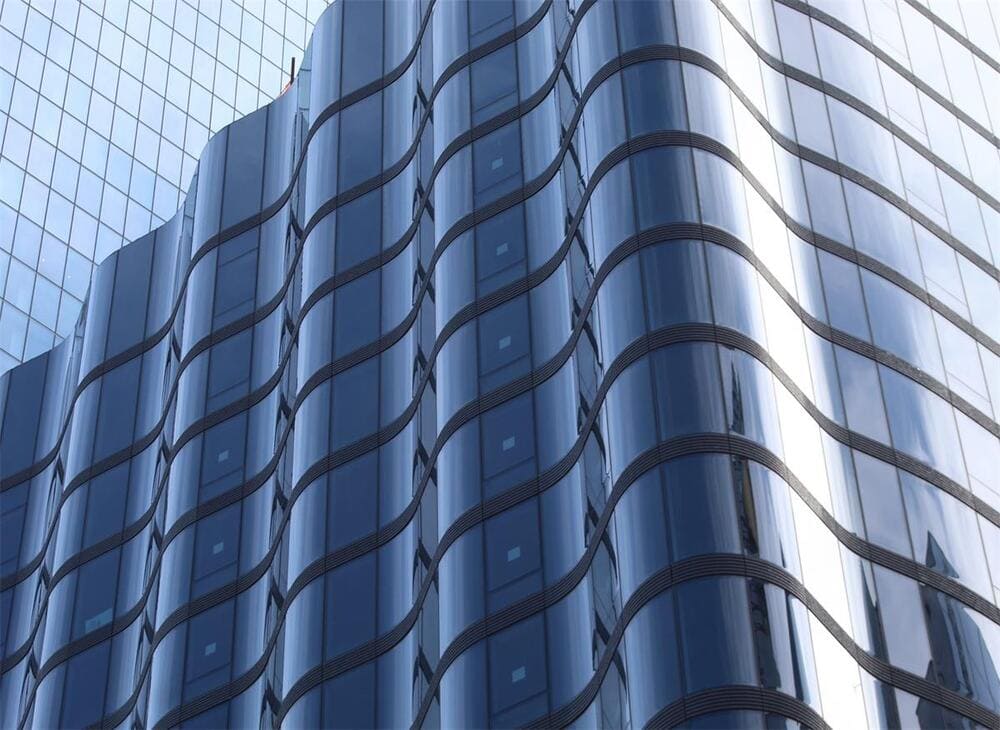

Sliding curved glass doors are ideal for modern architecture, commercial spaces, and luxury residences, offering seamless indoor-outdoor transitions, enhanced natural light, and sleek aesthetics. They excel in curved facades, hotel lobbies, retail displays, and smart homes. OrbGlass delivers custom solutions for radii as tight as 500mm, meeting global safety and design standards

Architectural Facades

Sliding curved glass doors transform building exteriors with fluid, energy-efficient designs. They maximize natural light while maintaining thermal efficiency, ideal for offices, museums, and cultural centers. OrbGlass provides structural engineering support and tempered glass options for wind load resistance up to 3,000 Pa.

Hospitality & Hotel Lobbies

Elevate hotel lobbies and resorts with automated curved sliding doors that enhance guest experiences. OrbGlass supplies laminated glass with noise reduction (up to 45 dB) and fire-rated options (EI 60-120), compliant with international hospitality safety standards.

Luxury Residential Entrances

Create grand entrances with curved sliding doors that blend elegance and functionality. Used in villas and penthouses, they offer panoramic views and space-saving operation. OrbGlass crafts bespoke designs with anti-fingerprint coatings and smart home integration, ensuring privacy and durability.

We Are Always Provide Best Sliding Curved Glass Doors For Your Project

Hear From Our Clients

We believe in creating long-term partnerships based on trust and quality. See what our clients say about working with us.

Sliding Curved Glass Doors Related Articles

What Is Curved Glass Called? (Complete Guide to Types)

2025-09-12

Top 9 Curved Glass Manufacturers Brazilian

2025-07-22

Top 9 Curved Glass Manufacturers in UAE 2025

2025-07-12

Top 8 Curved Glass Manufacturers South Africa 2025

2025-05-07

Top 7 Curved Glass Manufacturers Indian 2025

2025-05-07

Top 9 Curved Glass Manufacturers Australian 2025

2025-05-08

Top 10 Curved Glass Manufacturers UK 2025

2025-05-07

Top 10 Curved Glass Manufacturers USA 2025

2025-05-07

Top 10 Curved Glass Manufacturers 2025

2025-05-07

Get Started with OrbGlass Today!

Aerospace-grade CNC machines carve brass frames with micron-level accuracy, while AI vision systems inspect crystal cuts for refractive consistency. Even hidden parts undergo stress tests mimicking 10+ years of use.

- Material Traceability

Each brass sheet or crystal slab has a QR code linking to its origin and metallurgical report. - Self-Correcting Production

IoT-enabled machines adjust cutting paths in real time if material thickness varies. - Durability Validated

Salt spray chambers test finishes against humidity levels from Dubai villas to Nordic churches.