After working with architectural glass suppliers for 8 years and specifying curved glass for over 200 commercial projects, I’ve learned that most people get confused by the different terms – and it’s costing them money.

You’re looking at a beautiful curved glass storefront or that sleek smartphone in your hand, and you’re wondering what to call that bent glass. The terminology matters more than you think – especially if you’re trying to buy it, specify it for a project, or just want to sound knowledgeable when talking to contractors.

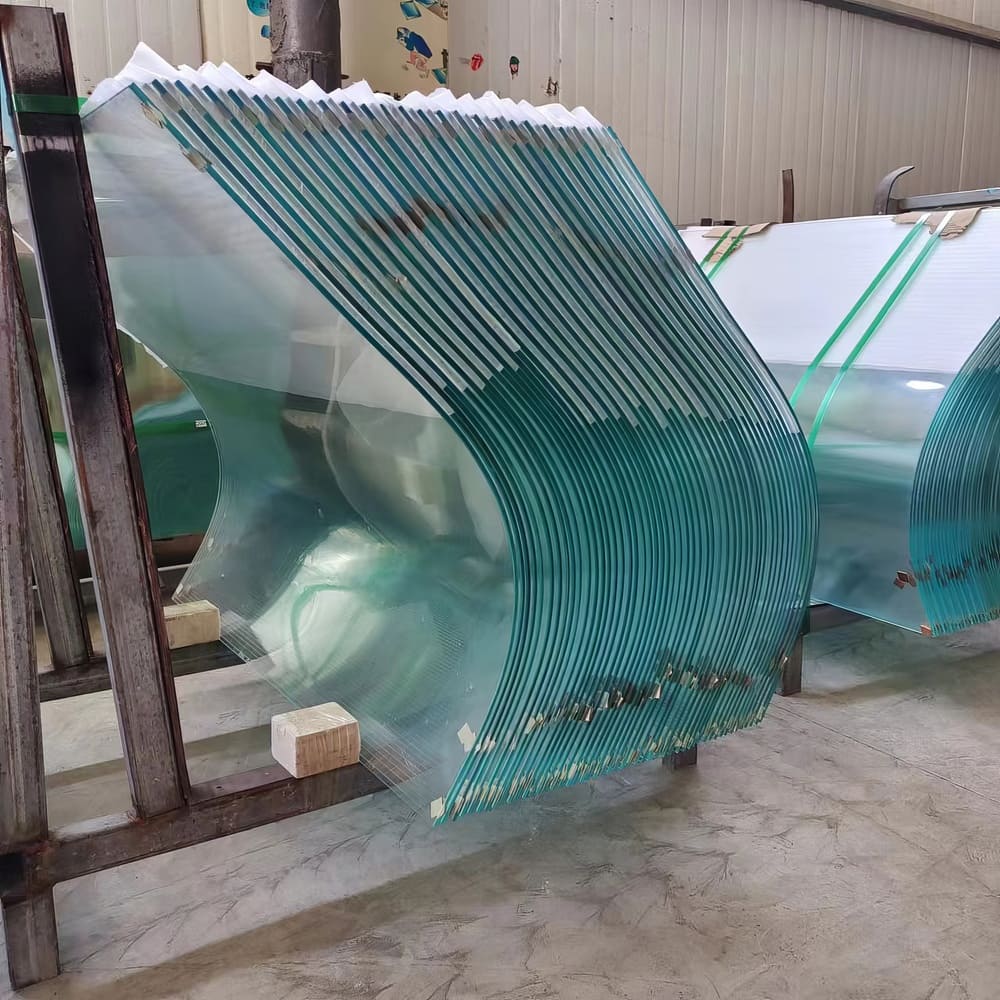

Curved glass is called “bent glass” in manufacturing, but specific types have distinct names: tempered curved glass, laminated curved glass, insulated curved glass, and slumped glass. The exact term depends on how it’s made and its intended use – using the wrong terminology can lead to quotes that are 300% higher than necessary.

I’ll walk you through the 6 main types of curved glass, when each is used, and the insider terminology that’ll help you get accurate quotes. Plus, I’ll share the one mistake I see architects make repeatedly that doubles project costs.

The Official Terms for Curved Glass

Let me clear up the confusion right away. In the glass industry, we don’t just say “curved glass” – that’s like saying “metal” when you need steel.

Bent Glass vs Curved Glass

“Bent glass” is the manufacturing term professionals use. When I call suppliers, I say “bent glass” and immediately get transferred to the right department.

“Curved glass” is the general public term. Nothing wrong with it, but it won’t get you far with manufacturers.

Here’s why the distinction matters: When you say “curved glass,” suppliers assume you’re a homeowner buying a small piece. Say “bent glass” and they treat you like a professional who knows what they’re talking about.

The 6 Types of Curved Glass You’ll Actually Encounter

Heat-Bent Glass (Most Common)

This is what most people think of as “curved glass.” The glass starts flat, gets heated to about 1,200°F, then bent over a form.

Where you see it:

- Storefront windows

- Display cases

- Curved shower doors

Industry term: “Heat-bent glass” or “furnace-bent glass”

Slumped Glass

The glass is heated until it becomes soft enough to slump into a mold under its own weight. This creates gentler curves than heat-bending.

Where you see it:

- Decorative glass panels

- Light fixtures

- Artistic installations

Industry term: “Slumped glass” or “sagged glass”

Cold-Bent Glass

Here’s where it gets interesting. Instead of heating the glass, it’s bent at room temperature and held in place by the glazing system. This only works with very gentle curves.

Where you see it:

- Large curtain wall systems

- Some smartphone screens

- Architectural facades

Industry term: “Cold-bent glass” or “structurally glazed bent glass”

Laminated Curved Glass

Multiple layers of glass with plastic interlayers, then curved. This is the stuff that holds together when it breaks.

Where you see it:

- Car windshields

- Hurricane-resistant windows

- High-security applications

Industry term: “Curved laminated glass” or “bent laminated safety glass”

Tempered Curved Glass

Glass that’s been heat-treated for strength, then curved. When it breaks, it crumbles into small pieces instead of sharp shards.

Where you see it:

- Glass doors

- Shower enclosures

- Table tops

Industry term: “Curved tempered glass” or “bent toughened glass”

Insulated Curved Glass

Two or more panes of curved glass sealed together with air or gas between them for insulation.

Where you see it:

- Energy-efficient windows

- Commercial building facades

- High-end residential projects

Industry term: “Curved IGU” (Insulated Glass Unit) or “bent sealed units”

How Curved Glass Gets Its Names

The naming follows a logical pattern once you understand it:

Process + Glass Type + Special Properties

For example:

- “Heat-bent tempered low-E glass” = heated into shape + strengthened + energy coating

- “Cold-bent laminated safety glass” = room temperature bending + multiple layers + safety rating

Understanding this formula helps you communicate exactly what you need.

The Costly Terminology Mistake

Here’s the expensive mistake I see repeatedly: People ask for “curved glass” when they really need “bent glass fabrication.”

What happens: You get quoted for custom one-off pieces instead of standard bent profiles.

Cost difference: $50 per square foot vs $150+ per square foot.

The fix: Ask specifically about “standard radius bent glass” first. Most common curves (like storefronts) use standard tooling that’s much cheaper.

I once saved a retail client $40,000 by switching from “custom curved glass panels” to “standard radius bent glass” – same visual result, standard manufacturing process.

Regional Name Variations

Different parts of the world use slightly different terms:

United States: “Bent glass,” “curved glass” United Kingdom: “Bent glass,” “curved glazing”

Australia: “Curved glass,” “bent glazing” Europe: “Bent glass,” “curved glass units”

The manufacturing processes are the same – just different words for the same thing.

When Precision Matters Most

Use the exact technical terms when:

- Getting quotes from manufacturers

- Talking to architects about specifications

- Ordering replacement glass for existing installations

- Discussing building codes with inspectors

Use general terms (“curved glass”) when:

- Explaining to clients what you’re installing

- Talking to general contractors who aren’t glass specialists

- Writing marketing materials for the public

My Quick Reference Guide

When you need curved glass, start with these questions:

- How is it curved? (Heat-bent, slumped, or cold-bent)

- What type of glass? (Tempered, laminated, or standard)

- Any special coatings? (Low-E, tinted, reflective)

- Single or multiple panes? (Monolithic or insulated)

Answer those four questions and you can communicate exactly what you need to any glass professional.

Your Next Steps

Before contacting suppliers:

- Measure your curve radius if possible (distance from center to edge of arc)

- Identify the glass type using the guide above

- Check if it’s a standard curve (common radii are often cheaper)

- Get multiple quotes using the exact terminology

I’ve created a simple measurement guide that shows you how to calculate curve radius and identify glass types from photos. You can download it along with my supplier contact template that uses all the right terminology.

For complex projects or if you’re specifying curved glass for the first time, consider consulting with a glazing contractor who can help you navigate the options and ensure you’re using the most cost-effective approach.

The bottom line? “Curved glass” might be technically correct, but knowing the specific terms will save you time, money, and confusion when you actually need to buy or specify it.

Based on 8 years of architectural glass specification and over 200 curved glass installations across commercial and residential projects.